Tubular heat exchangers are often used for heating or cooling gaseous media, such as air coolers for internal combustion engines. Hot water flows in the tubes, which are surrounded by a flowing gaseous medium, e.g. cold air. The hot medium emits some of its thermal energy to the cold medium.

The tubes are fitted with fins in order to increase the heat transfer surface and thus improve the convective heat transfer.

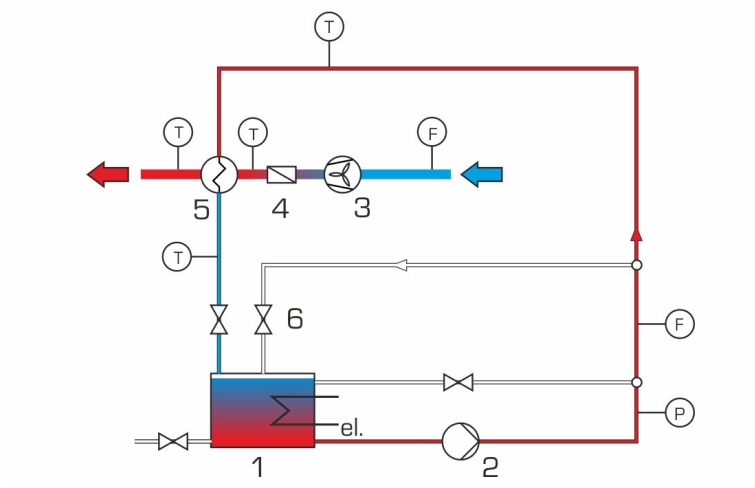

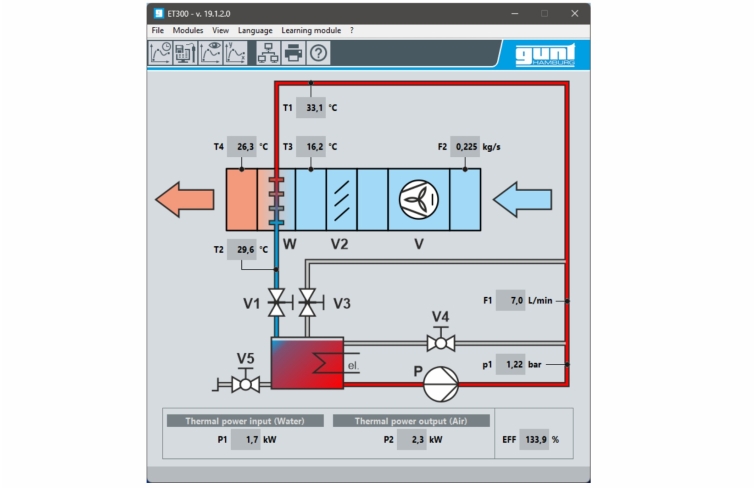

The ET 300 trainer is used for quantitative investigations on a finned-tube heat exchanger using the media hot water and cold air. The core element of the trainer is an air duct with fan, in which a finned-tube heat exchanger is installed.

A streamlined inlet element and a flow straightener in the air duct provide a homogeneous flow for carrying out the experiment. The volumetric flow rate is adjusted via a throttle valve at the fan outlet and measured by a measuring nozzle at the inlet into the fan.

The trainer has a closed hot water circuit consisting of: water tank with heater, pump, adjustable flow rate, electromagnetic flow rate sensor and finned-tube heat exchanger. The flow rate can be adjusted via a valve.

Energy balances can be established by measuring the inlet and outlet temperatures and the flow rates. In addition, a pressure sensor in the water circuit makes it possible to plot a pump characteristic. The measured values are read from digital displays and can be transmitted simultaneously via USB directly to a PC, where they can be analysed using the software included.