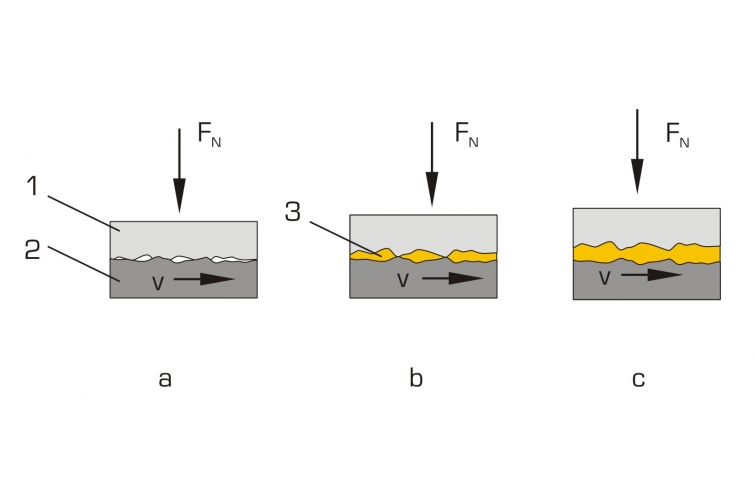

In bearing and drive technology, dynamic friction occurs at the sliding and rolling points, which leads to power losses in the technical systems. Dynamic friction is differentiated into sliding, rolling and spinning friction. In dynamic friction, there is relative translation between the two bodies.

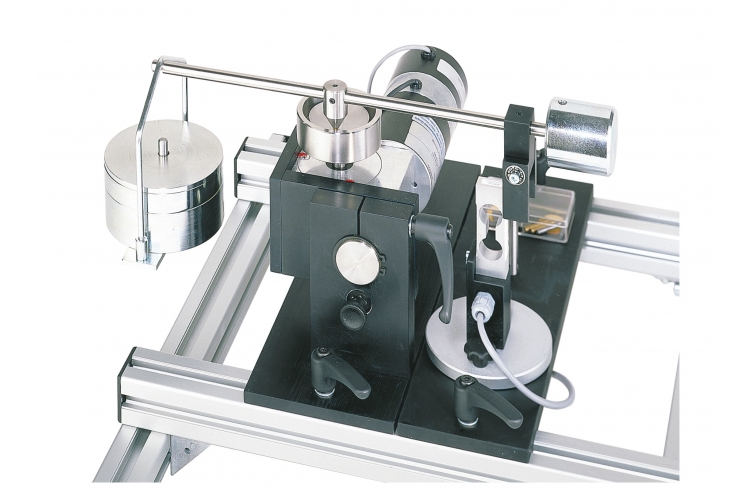

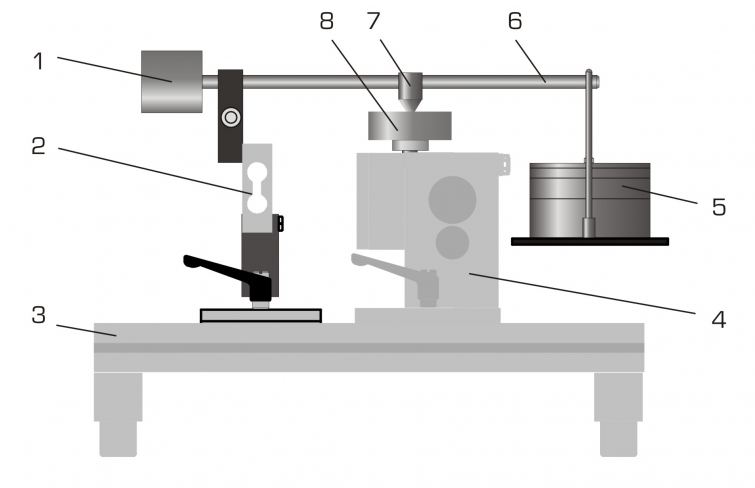

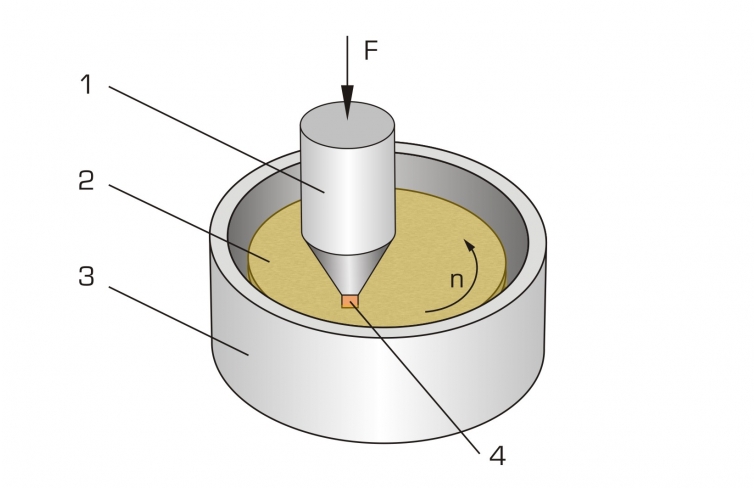

The tribological system in TM 260.03 allows a clear representation of the dynamic friction and an analysis of the frictional forces. The experimental unit contains a fixed pin that is pressed axially against a rotating disk as the friction pair. The contact force between the friction partners can be adjusted gradually up to a maximum of 80 N by means of a lever. The rotating disk is enclosed by an open cup that can be filled with different lubricants for the experiments.

Different lubrication conditions can be studied, such as dry friction, water or oil lubrication. Pins made of different materials are included in the scope of delivery to study different friction pairings.

The TM 260 drive unit is required in order to conduct experiments. The experimental unit is mounted quickly and easily on the frame of the drive unit with quick-action chucks. The disk is driven by a clampable coupling between drive unit and gear unit. The display and control unit of the drive unit shows frictional force and speed and allows the continuous adjustment of the speed.

The frictional force and the coefficient of friction can be determined in experiments. The frictional forces are measured by a force sensor. The wear can be determined precisely by measuring the change (reduction) in length of the pin.