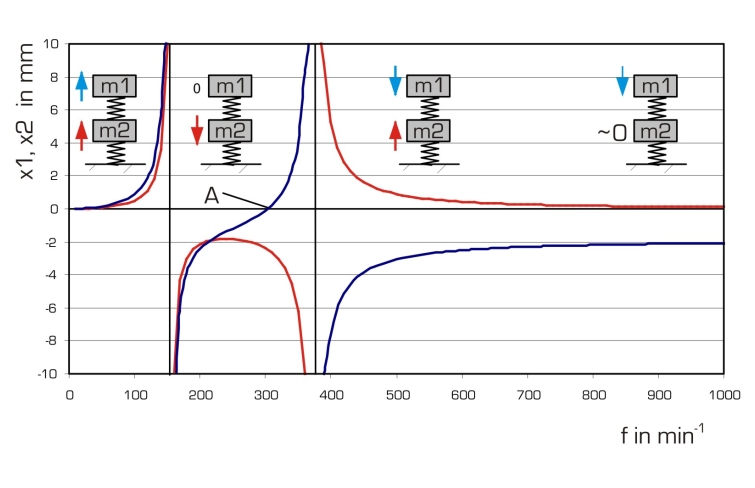

An indispensable part of machine design is the reduction of vibrations. For example, an elastic, vibration-isolating setup of the machine avoids disruptive vibrations being transferred to the surroundings.

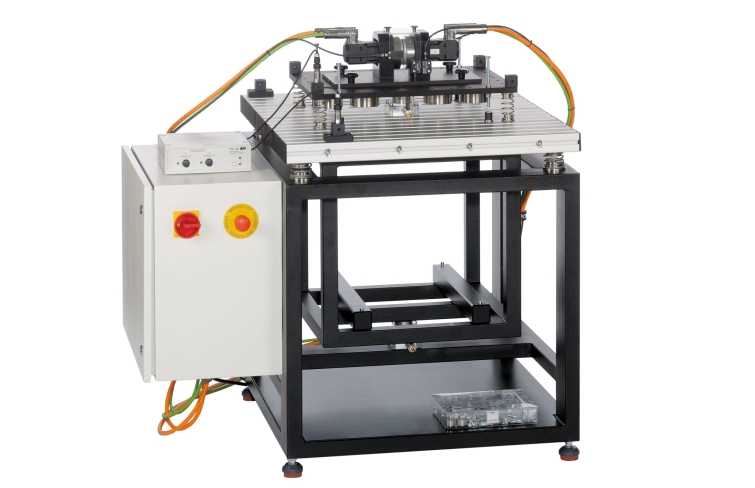

The TM 182 unit can be used to study the issue of machine foundations and isolation from vibrations using a practical example. To do this, vibrations are deliberately produced on an elastically mounted machine. The transfer of these vibrations to the foundation is measured. It is then possible to test different adjustments using different springs and to study absorbing effects using vibration absorbers.

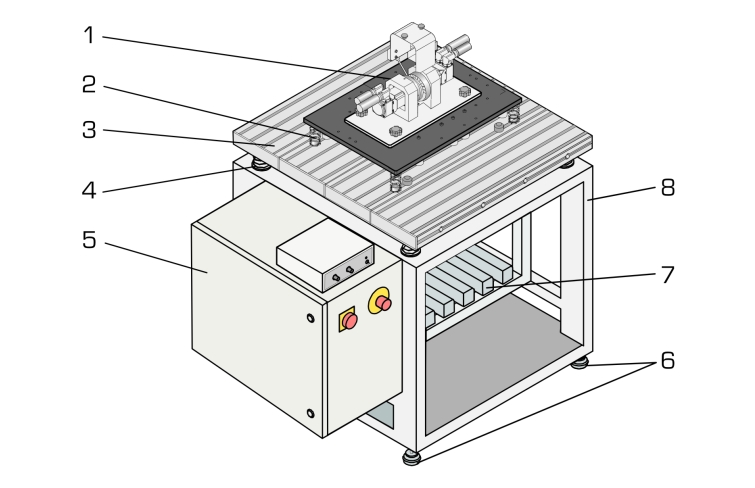

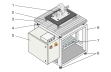

The experimental setup consists of a machine, a foundation and a frame. A vibration generator serves as the machine, consisting of two independently driven imbalance sets. The imbalance sets are driven by servomotors so that any excitation forces and force directions can be generated. Alternatively, a piston compressor (TM 182.01) can be used to generate vibrations.

The machine is mounted on a foundation by means of springs and dampers. The surroundings are represented by the foundation, on which the effectiveness of the vibration isolation is measured.

The foundation is connected to the actual frame of the trainer via additional coil springs. This dual vibration isolation, together with the large weight of the foundation itself, guarantees a vibration-free operation in the laboratory even under unfavourable experimental conditions. A switch cabinet is attached to the frame, housing the control system, power supply and data acquisition.

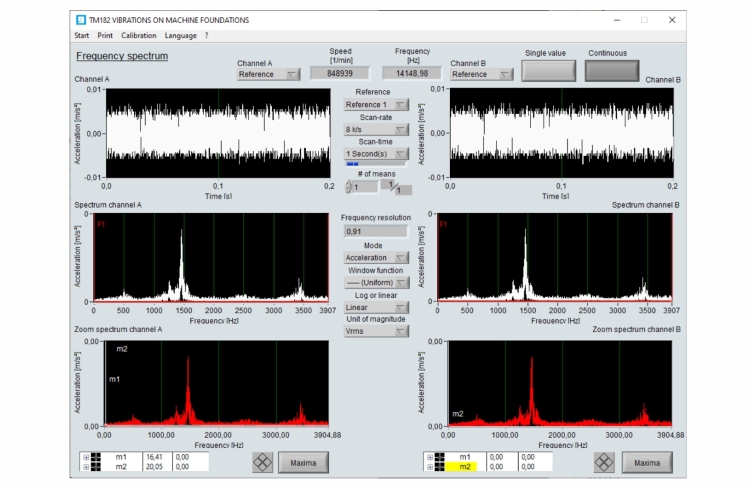

Acceleration sensors are used to measure deflection, velocity and acceleration of the vibrations at different points. Using these measured values, it is possible to calculate and display the operational vibration modes.

A comprehensive software program is provided to control the operating conditions and to capture and analyse the data. The unit is connected to the PC via USB.