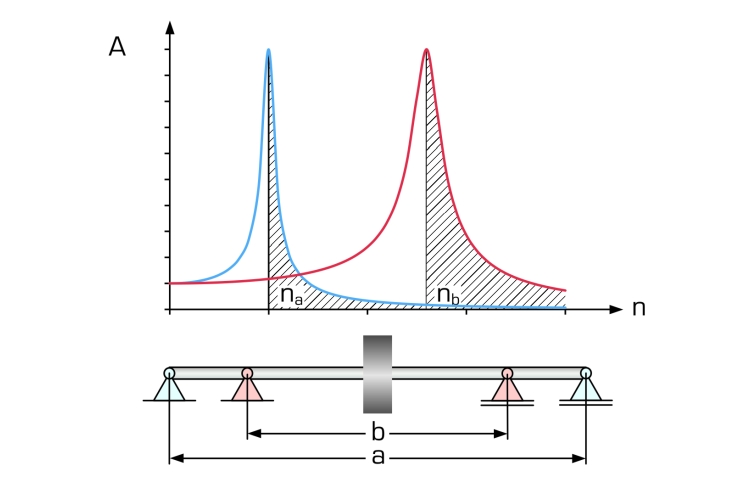

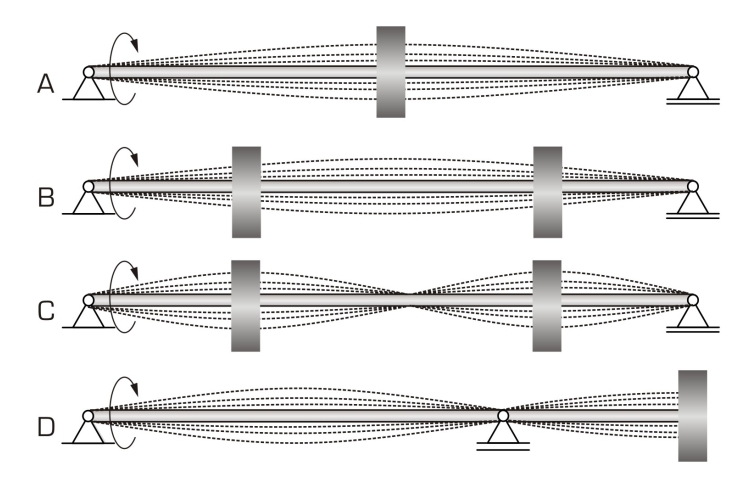

Critical speed and resonance are phenomena that play essential roles in many machines and systems. In particular, resonance states with impermissibly high vibration amplitudes can occur in rotating shafts and rotors at certain speeds, which in some cases can even lead to destruction of the machine. To prevent this, the system is operated well above or below the critical speed and driven quickly through the critical speed range. Therefore, knowledge of critical speeds and vibration modes is important in the design and operation of machines with bending elasticity in their rotors.

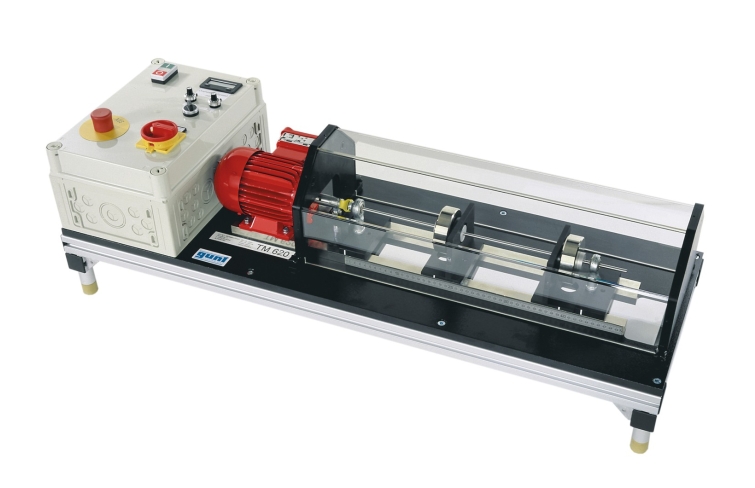

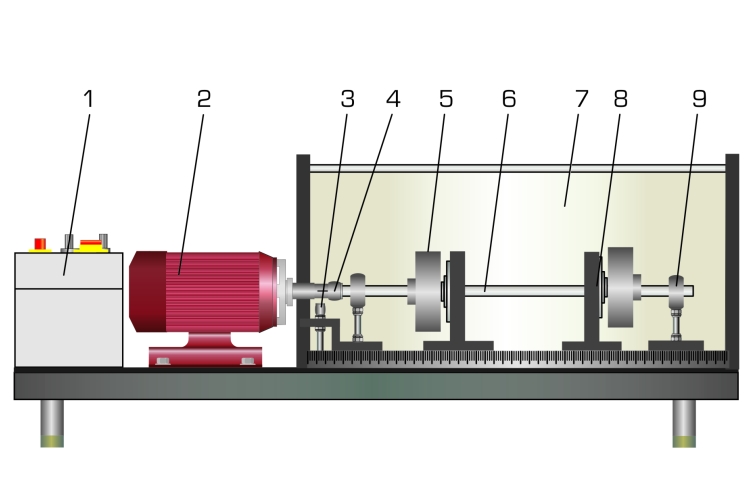

The TM 620 experimental unit can be used to clearly demonstrate phenomena such as resonance, self-centring and vibration modes. The model-like structure of the experimental rotor as a thin, elastic shaft with rigid mass disks allows simple theoretical comprehension of the vibration phenomena that occur.

The influence of different parameters can be studied thanks to the free choice of bearing and disk arrangement. The limitation of the amplitudes at a rapid resonant cycle can also be demonstrated.

A three-phase motor drives a rotor shaft, onto which one or two masses may be fixed at various distances. The rotor shaft is mounted in two self-aligning ball bearings and connected to the motor via a flexible coupling. The electronically controlled speed can be selected via two potentiometers and is continuously variable. It is displayed on a digital display.

The positions of and distances to elements fixed onto the rotor shaft can be read on a scale mounted in parallel with the rotor.

A transparent protective cover and safety bearings immediately next to the masses ensure safe operation.

The measured values can be displayed and analysed on a PC using the optional TM 620.20 unit for data acquisition.