The belt drives are machine elements that are classed as traction mechanisms in the field of transmission or conversion elements. They transfer torque and speed between guiding members such as wheels or pulleys. The motion is transferred by traction mechanisms that can only absorb tensile forces. Toothed belts and chains deliver positive transmission of movements. Traction mechanisms such as cables, flat belts and V-belts, on the contrary, allow for non-positive transmission.

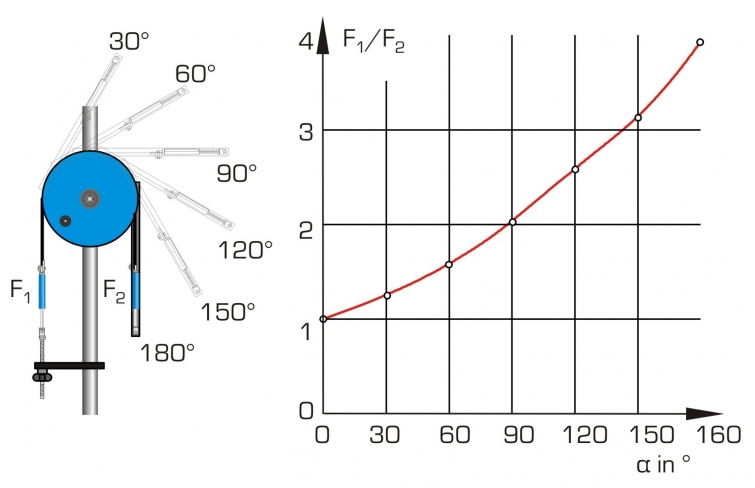

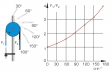

In non-positive belt drives, the circumferential force between the belt and the pulley is transmitted according to the principle of cable friction.

Cable friction arises due to tangential static-friction forces at the points where the cable is in contact with the wheel or the pulley. Eytelwein’s cable friction formula is used to calculate both cable and belt friction.

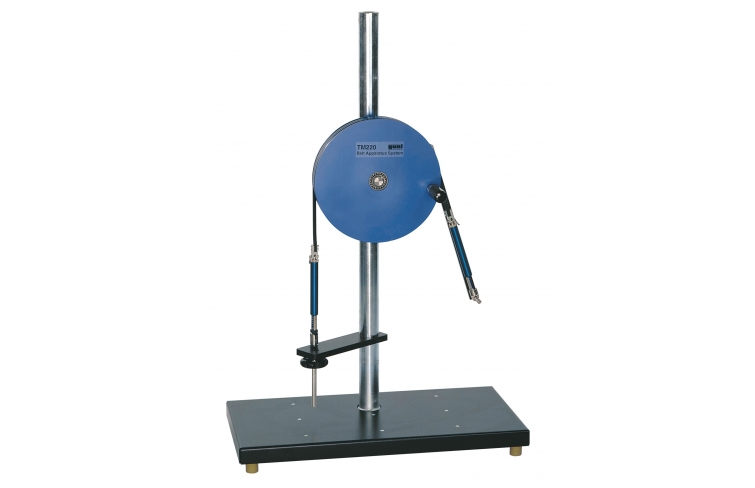

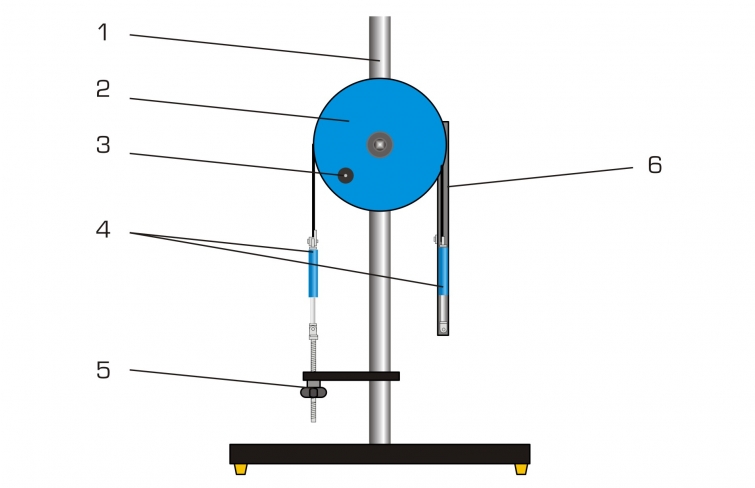

The TM 220 experimental unit allows the study by experiment of belt drives and belt friction. At the core of the experimental unit is a cast iron pulley, whose circumference features grooves for V-belts and flat belts. The pulley is mounted on ball bearings and is powered by a crank handle. Its flywheel mass favours an even rotation of the pulley. The belts rub on the pulley at a wrap angle between 30° and 180°. The wrap angle can be adjusted in increments of 15°.

Two spring balances detect the tensile forces on the respective belt ends. This makes it possible to precisely adjust the belt tension using a threaded spindle.

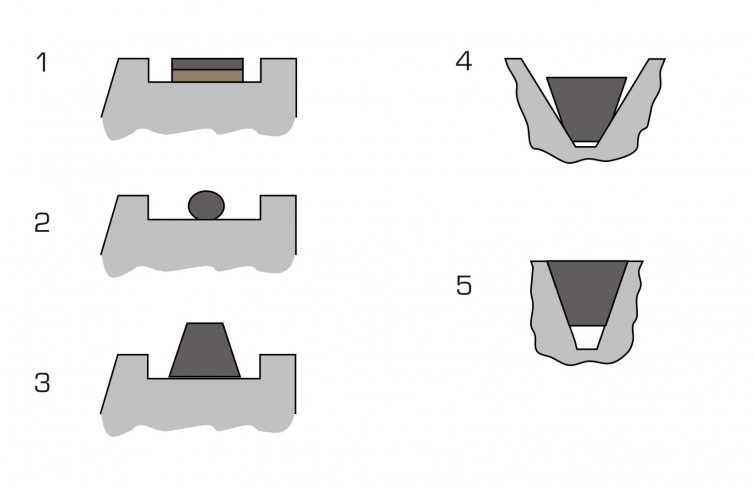

Two flat belts made of different materials, a V-belt and a cable belong to the scope of delivery. The experiments compare different belt types and materials and investigate the effect of the wrap angle.

In addition, for V-belts, it is possible to study how the groove shape affects the coefficient of friction.