This accessory for WP 310 makes it possible to investigate the material properties of thin sheet metal. To do this, the specimens are deformed in practice-oriented cupping experiments and then examined.

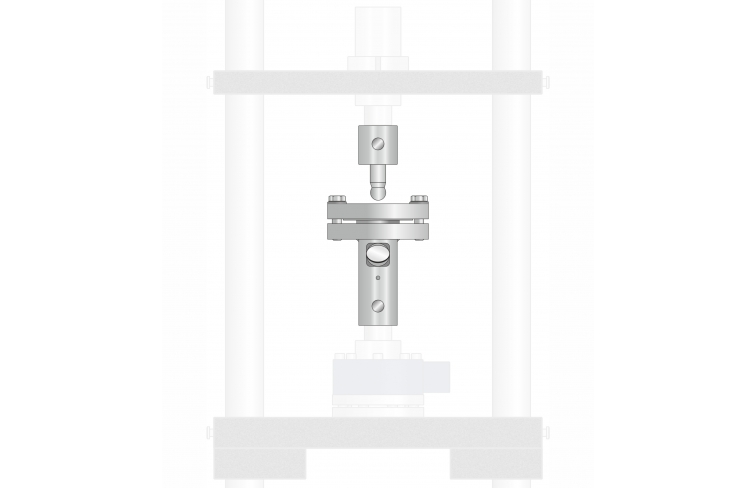

The accessory contains a punch, a hold-down clamp, a die and a mirrored cylinder for analysing the specimen. The assembled test device is installed in the compression area of the WP 310 experimental unit, between bottom crossbar and crosshead.

A thin sheet metal specimen is clamped between the die and the hold-down device.

The specimen in then deformed until it cracks by means of a spherical drawing punch. The mirror allows you to observe the specimen from below and to see exactly when the crack starts. Thin sheet metal with a thickness up to 2mm can be studied with the device.

The depth achieved in mm is defined as a standard of comparison for cold formability. In addition, the type of the rupture and the surface structure of the sagging area are analysed.

A set of specimens is included to carry out experiments. The set contains one specimen each of aluminium, copper, brass and steel.