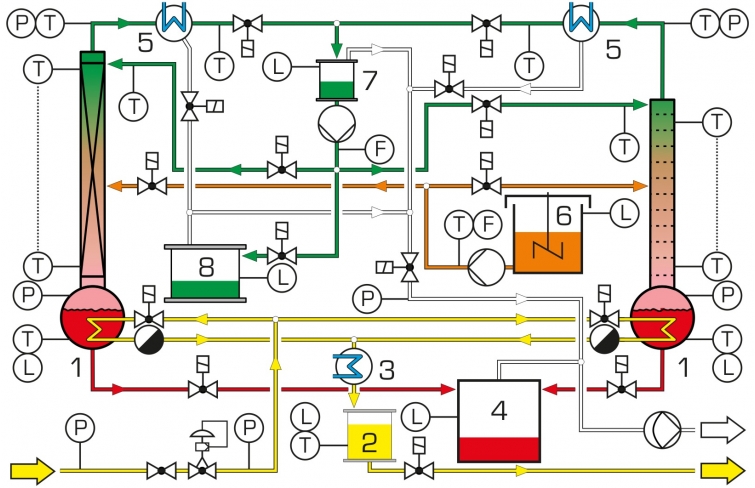

The rectification columns are used for the separation of liquid phases. They operate according to the principle of distillation. Distillation is a separation process that includes the partial evaporation of a liquid phase and the condensation of the resulting gas phase. The separation process of rectification is an energy-efficient distillation process with several stages. The substance mix recommended for the operation of the experimental plant is water-ethanol.

The CE 610 experimental plant is designed for the continuous operation of one rectification column at a time. The rectification columns are a packed column with pall rings and a sieve tray column with ten trays.

You can adjust various process parameter for the investigation of the rectification columns. These include, for example, the reflux ratio and the temperature measuring point for the temperature control. The effects of the changes are determined by means of the proportion of ethanol in the products (gravimetric measurement) thus also determining the separating capacity. For the evaluation of the experiments the software can be used to determine the theoretical separation steps by means of a McCabe-Thiele Diagram and the HTU-NTU concept.

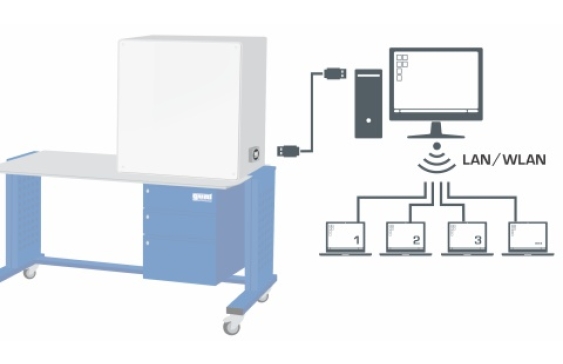

The experimental plant is equipped with a comprehensive range of functions for measurement, control and operation that are controlled by a PLC. A touch panel displays the measured values and operating states and can be used to control the plant. At the same time, the measured values can be transmitted directly to a PC via USB where they can be analysed with the software.

The steam supply is realised via the laboratory supply or the optionally available electric steam generator (CE 715.01).