The experiments familiarise students with various pump types, such as centrifugal and positive displacement pumps.

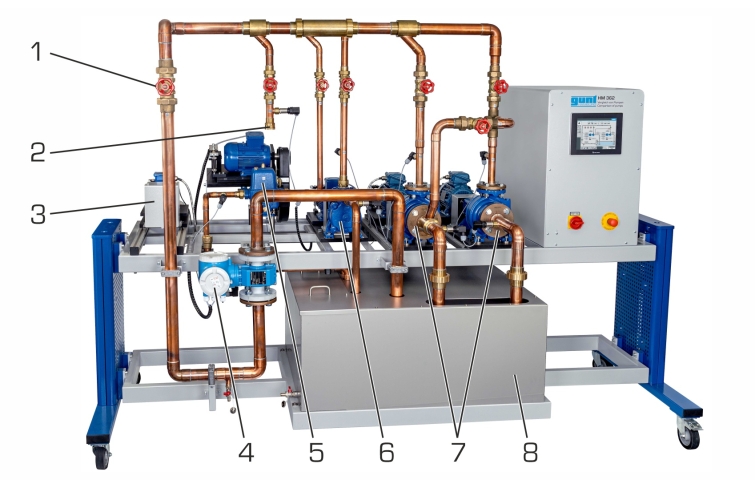

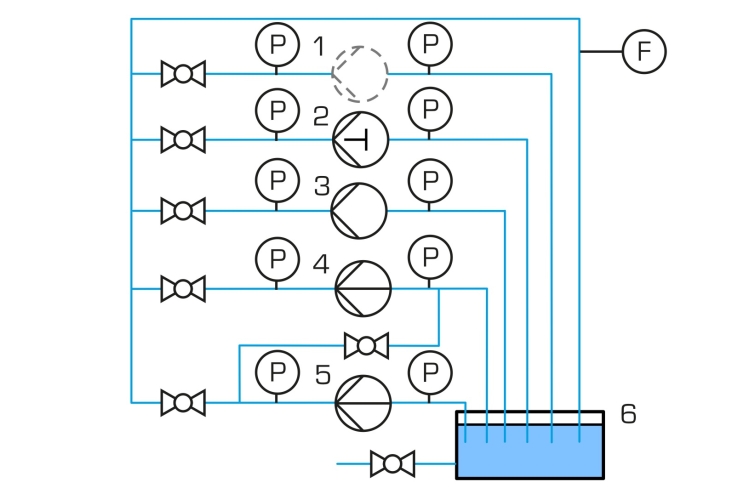

The HM 362 trainer includes two centrifugal pumps, one piston pump as a positive displacement pump and a self-priming side-channel pump. The side-channel pump works primarily as a centrifugal pump and, depending on liquid level, can also act as a positive displacement pump. This means, as a special feature, the side-channel pump also permits gases to be pumped.

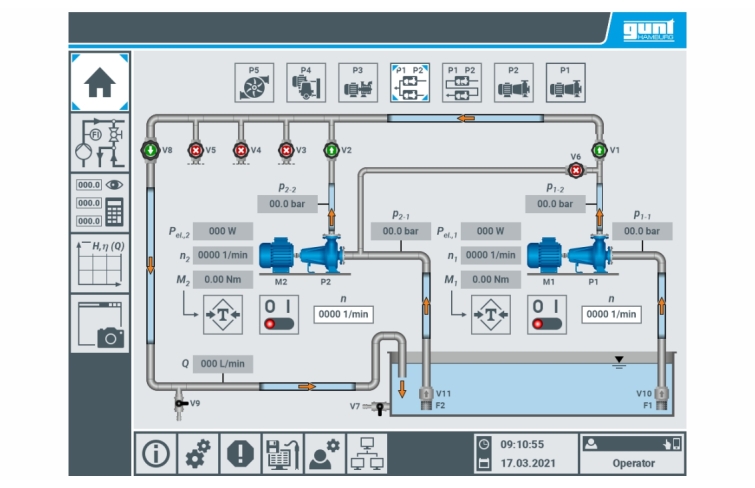

The pump being investigated pumps water in a closed circuit. In the process, the performance data of the pump and pressure losses in the pipeline are recorded. The centrifugal pumps can also be operated in parallel or in series configuration. Each pump is driven by a separate three-phase AC motor. The speed of the motors for the centrifugal pumps is variably adjustable by a frequency converter. All motors are mounted on swivel bearings, so the torque can be measured by way of a force sensor, enabling the mechanical drive power output to be determined.

One free position is likewise equipped with a reversible three-phase AC motor with variable speed. This position can be used for mounting of any pump. Experiments demonstrate the basic operating behaviour of various pump types.

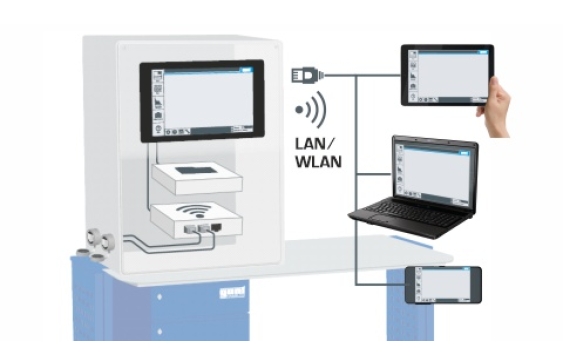

The trainer is operated and controlled by the integrated PLC with touch screen. By means of an integrated router, the trainer can alternatively be operated and controlled via an end device. The user interface can also be displayed on up to 10 end devices (screen mirroring). Via the PLC, the measured values can be stored internally. Access to stored measured values is possible from end devices via WLAN with integrated router/LAN connection to the customer’s own network.