PPT

PPT

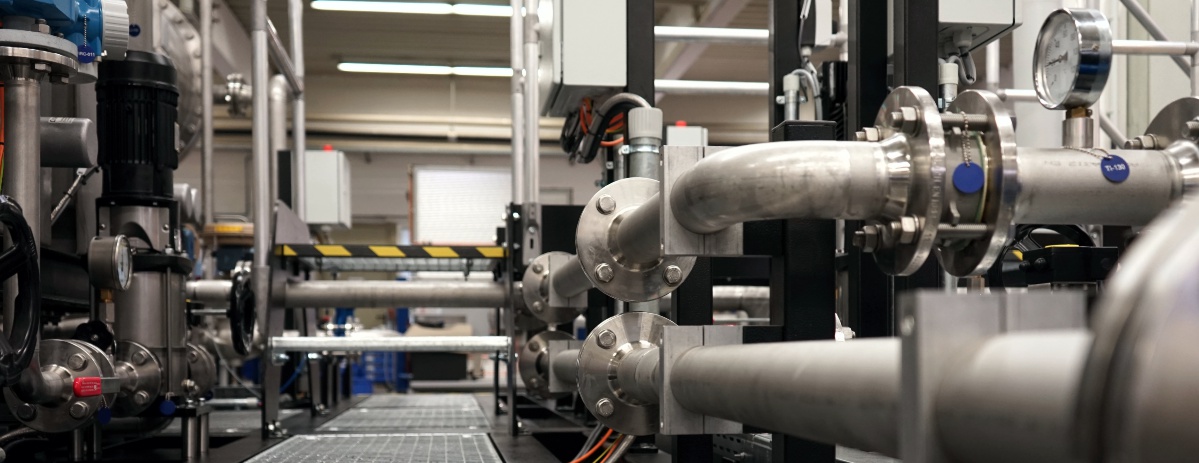

Process pump trainer

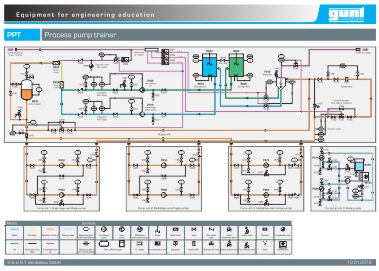

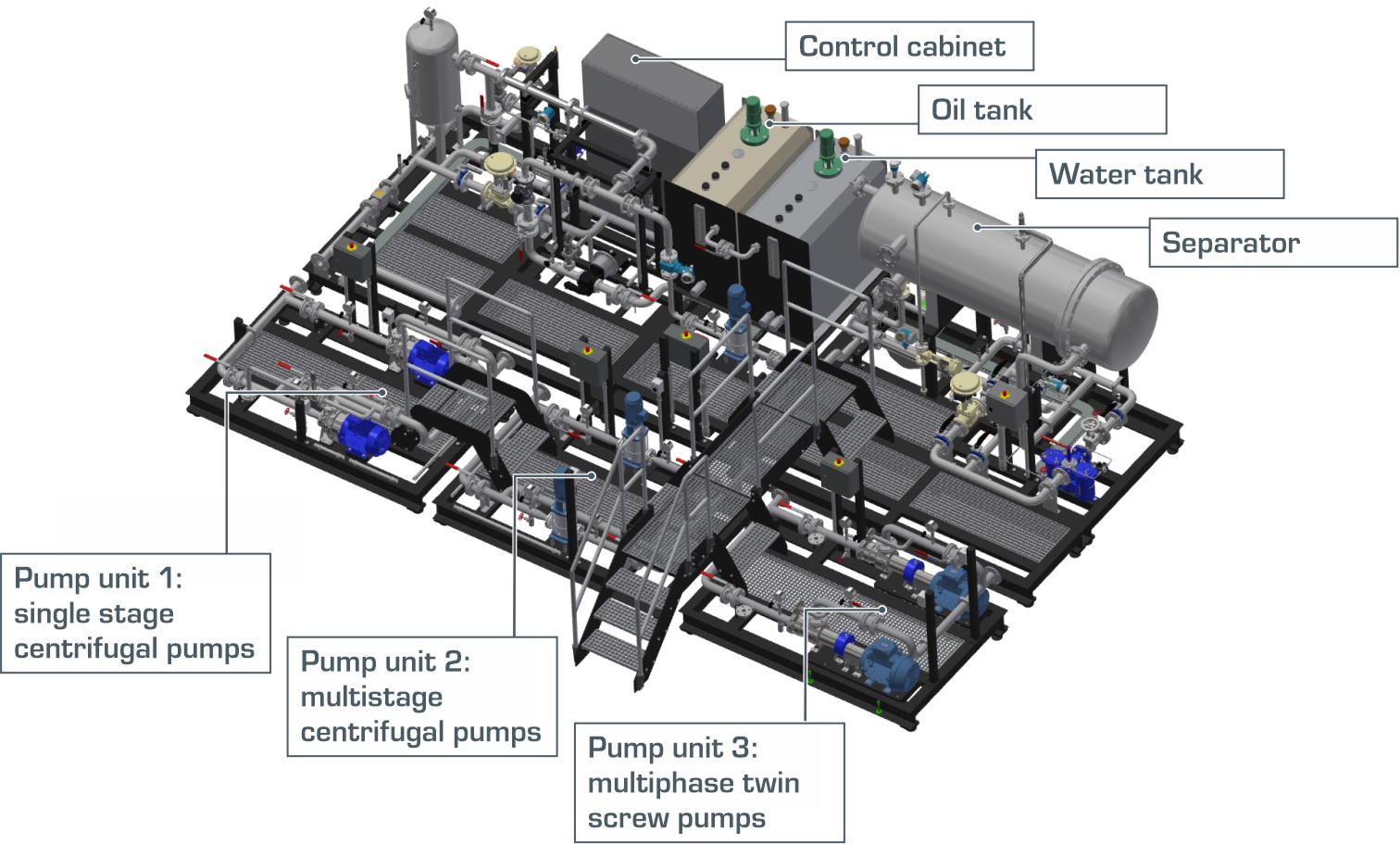

In oil industry, crude oil is extracted from a well and then pumped for further processing. In the process pump trainer (PPT) three different pump types are operated and compared in various operation modes. The working medium is a mixture of air, water and oil to simulate crude oil. The trainer consists of three pump units and one supply unit. Each pump unit is equipped with two identical pumps. Pump operation in line or parallel is possible.

After passing the pump section, the synthetic crude oil is split into oil, water and air by phase separation and is then re-mixed to ensure its homogeneous composition.

Operating modes of the pump units

Pump unit 1: Single stage centrifugal pumps

- one pump in single operation

- two pumps in parallel operation

- two pumps in series operation

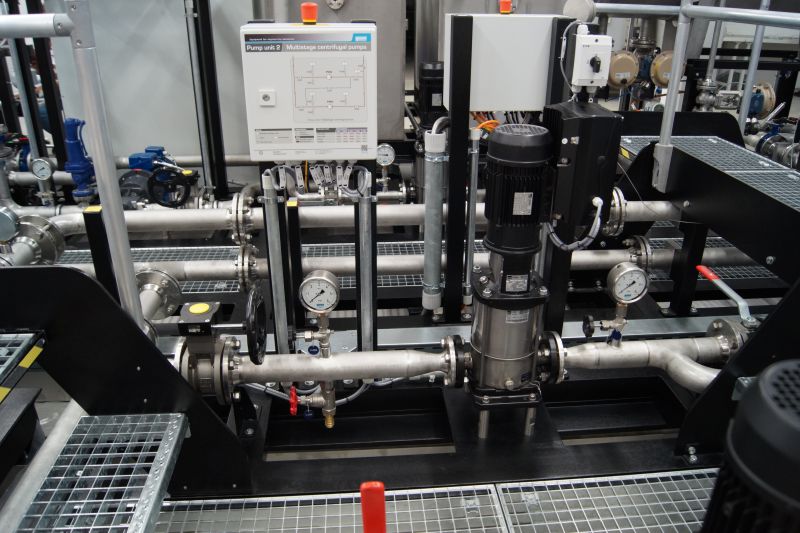

Pump unit 2: Multistage centrifugal pumps

- one pump in single operation

- two pumps in parallel operation

- two pumps in series operation

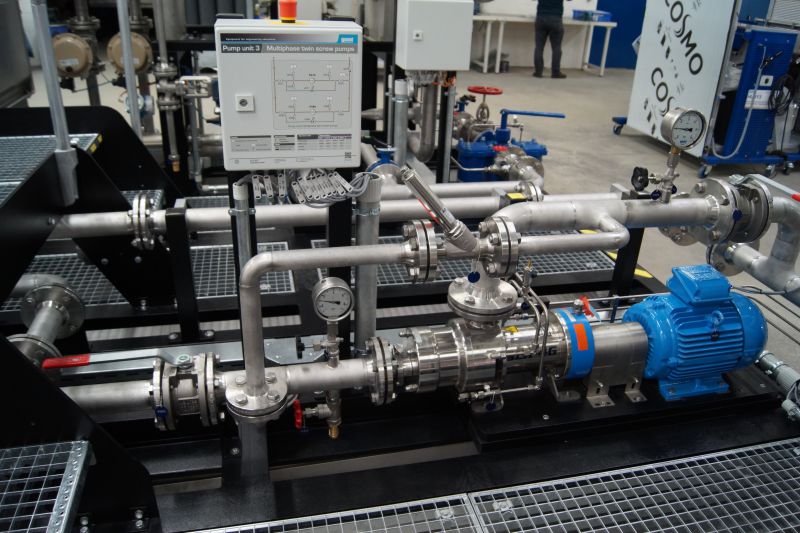

Pump unit 3: Multiphase twin screw pumps

- one pump in single operation

- two pumps in parallel operation

Learning objectives

General learning objectives

- operation of different pumps

- process engineering

- instrumentation & process control engineering

More specific learning objectives

- reading piping and instrumentation diagrams (P&IDs), locating appropriate components

- behaviour of different pump types with several operating modes

- single stage centrifugal pumps: single, parallel and series operation

- multistage centrifugal pumps: single, parallel and series operation

- multiphase twin screw pumps: single and parallel operation

- function of redundancy in plants

- behaviour of control loops (temperature, pressure and flow)

- setting parameters at PID controllers (proportional, integral, derivative)

- three phase separation

Download