IUI

IUI

lnspection Unit for Industry

Knowledge of industrial components plays an important role in the training of industrial inspectors. In order to acquire this knowledge it is very helpful to practice on plants with components in real scale.

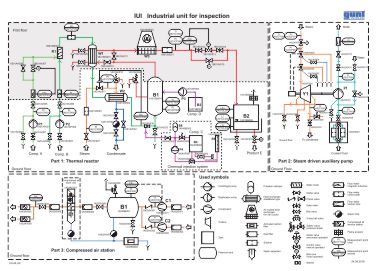

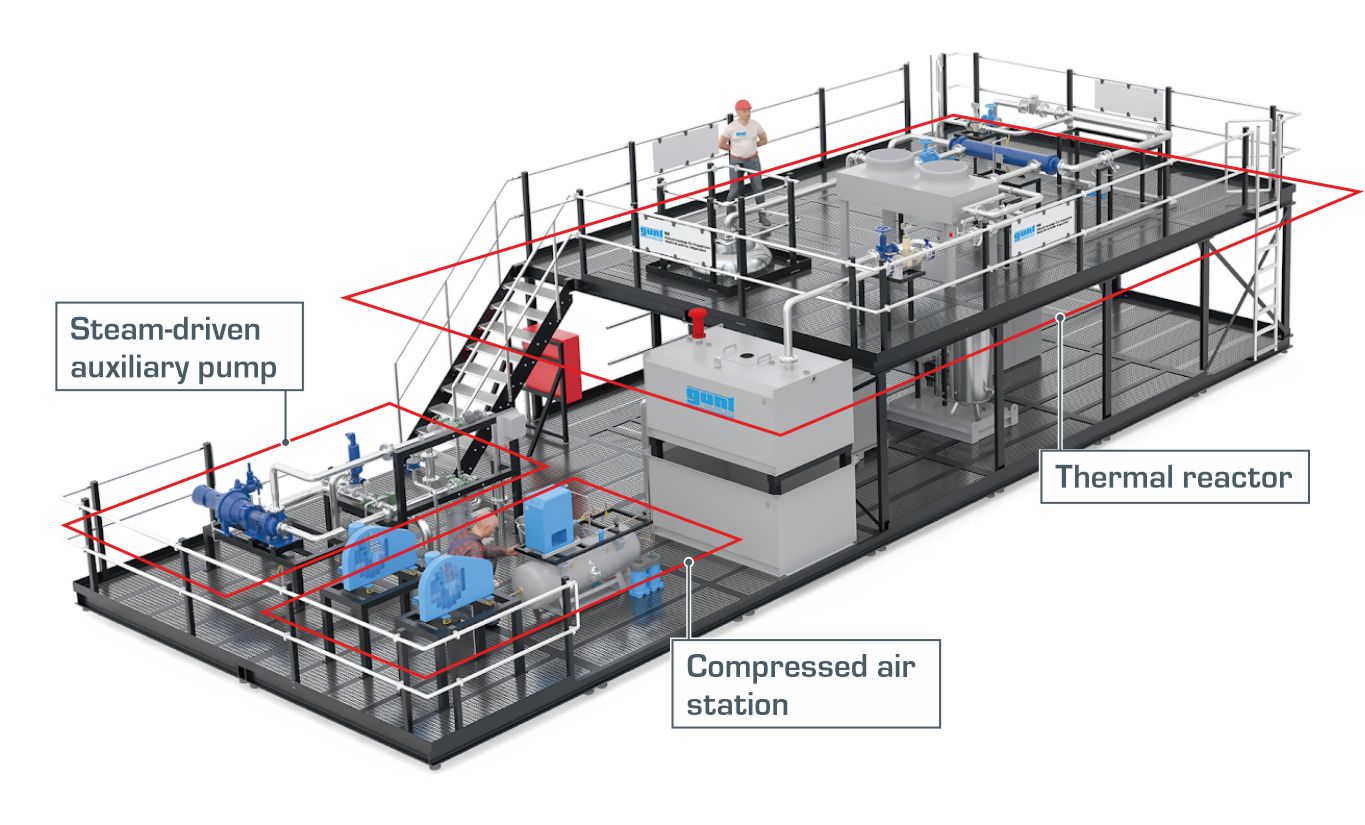

The demonstration unit consists of three parts: a thermal reactor, a steam driven auxiliary pump and a compressed air station. All of these parts are connected via pipes and valves. A variety of electrical components such as cables, switches, contactors, displays, fuses and a switch cabinet show typical electrical cabling as in a real-world plant.

Part 1: Thermal reactor with chemical injection system

This section shows an example of a thermal process. Two feed materials A, B (liquid) are pumped by two centrifugal pumps to a static mixer. The mixed feed material then flows through a first heat exchanger. In the subsequent steam-heated heat exchanger, the feed material is brought to its final reaction temperature. The heated feed material is then mixed with component C. This is done via a chemical injection system. The mixture enters reactor from below. The finished product E leaves the reactor at the upper end and transfers part of its heat to the feed material in the first heat exchanger. A dry cooling tower then finally cools down the product. The product is then stored in an intermediate tank.

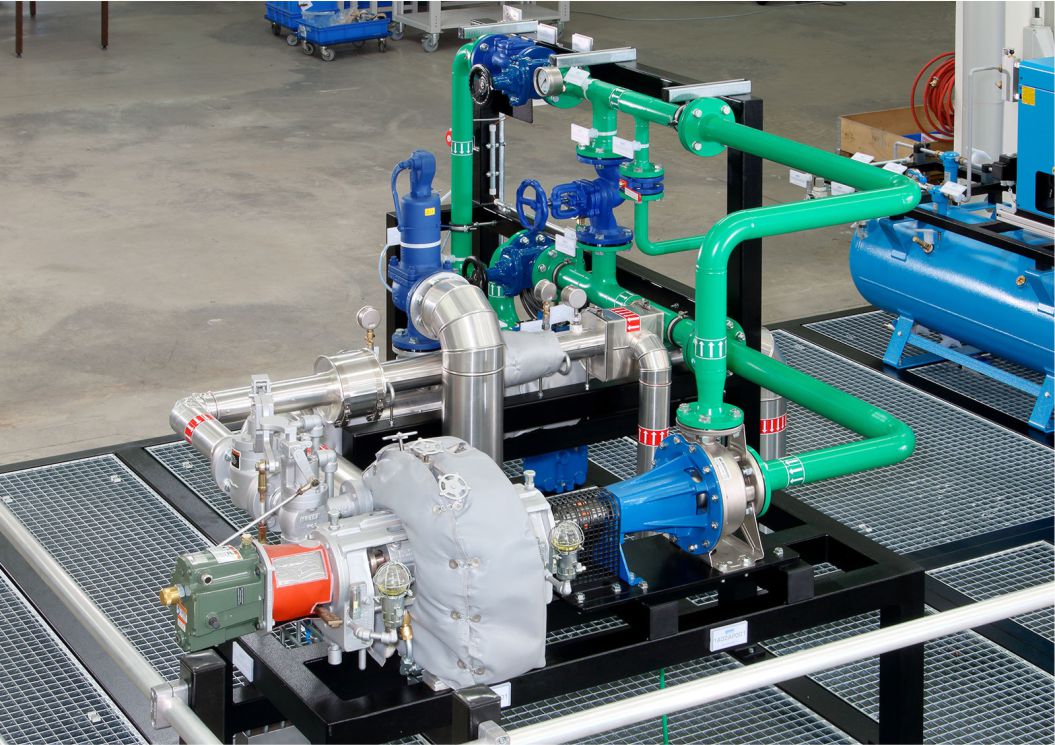

Part 2: Steam-driven auxiliary pump station

This part of the plant shows a steam-driven auxiliary pump. These pumps are used in industry as backup systems. In the event of a malfunction, e.g. power failure, the backup pump conveys important liquids such as coolants or lubricants, thereby protecting other components from damage. For this purpose, these components run purely mechanically and do not need electricity.

The pump station consists of an industrial steam turbine and a directly driven centrifugal pump.

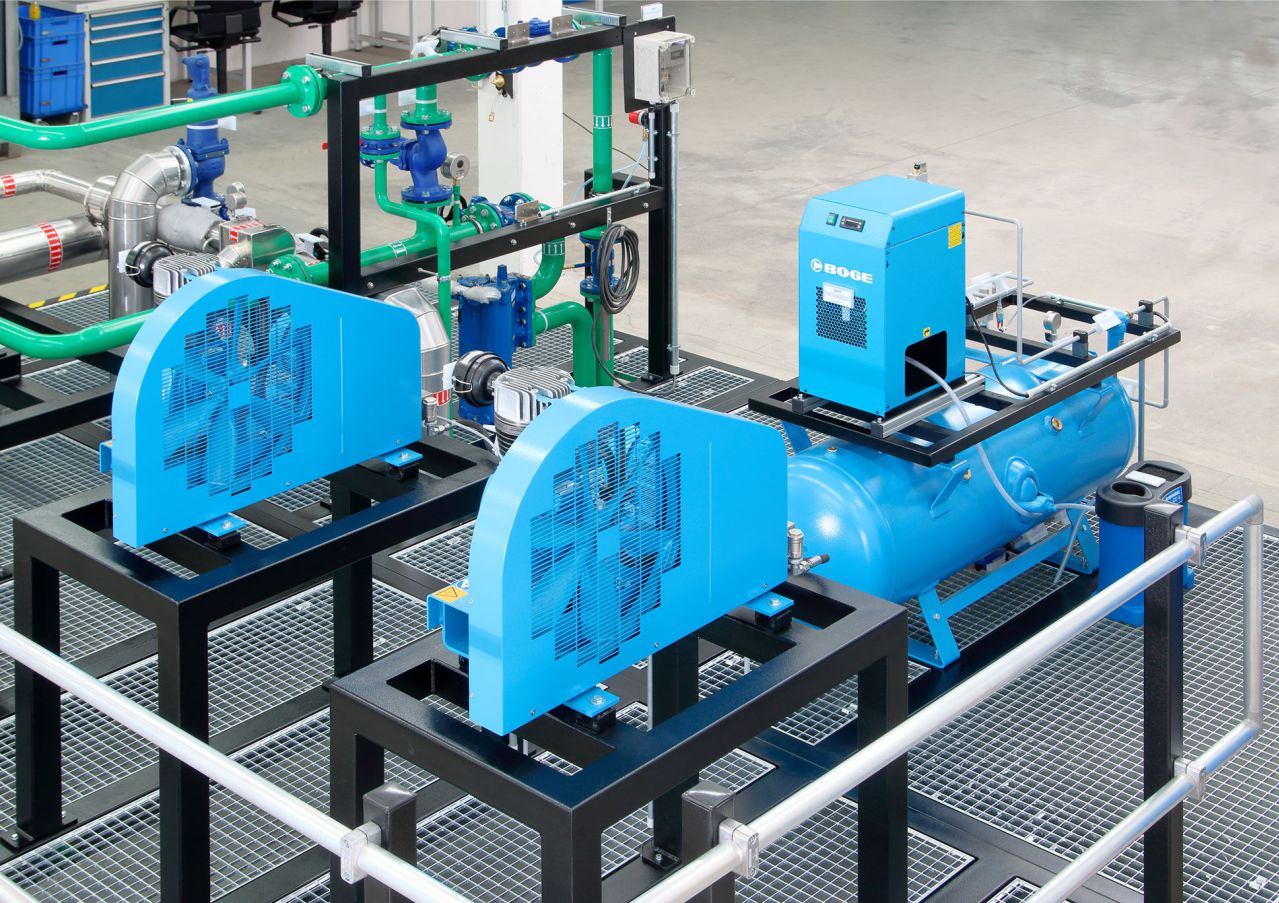

Part 3: Compressed air station

This part of the plant shows a compressed air supply station. It essentially consists of two identical compressors, a horizontal pressure tank and a compressed air dryer.

Learning objectives

The following learning objectives can be achieved when working with the training plant:

- familiarisation with a variety of components typical of the oil industry

- learning how components are integrated in a complex process plant

- identification of plant components

- typical characteristic technical data of components

- understanding technical documentation

- comparison of the technical specification with the technical data of the real-world equipment

- finding differences between technical documentation and real equipment

- learning to read technical drawings

- learning to read electrical circuit diagrams

- learning the typical symbols in technical drawings

- learn how to read P&ID flowcharts

Download