Pilot plants & training plants

Pilot plants & training plants

Training solutions for the process & energy sector

GUNT has been known for decades as the leading manufacturer of educational systems, popular in engineering departments of universities and colleges.

Another field of GUNT’s activities are industrial training plants to cater for the specific training needs of the industry.

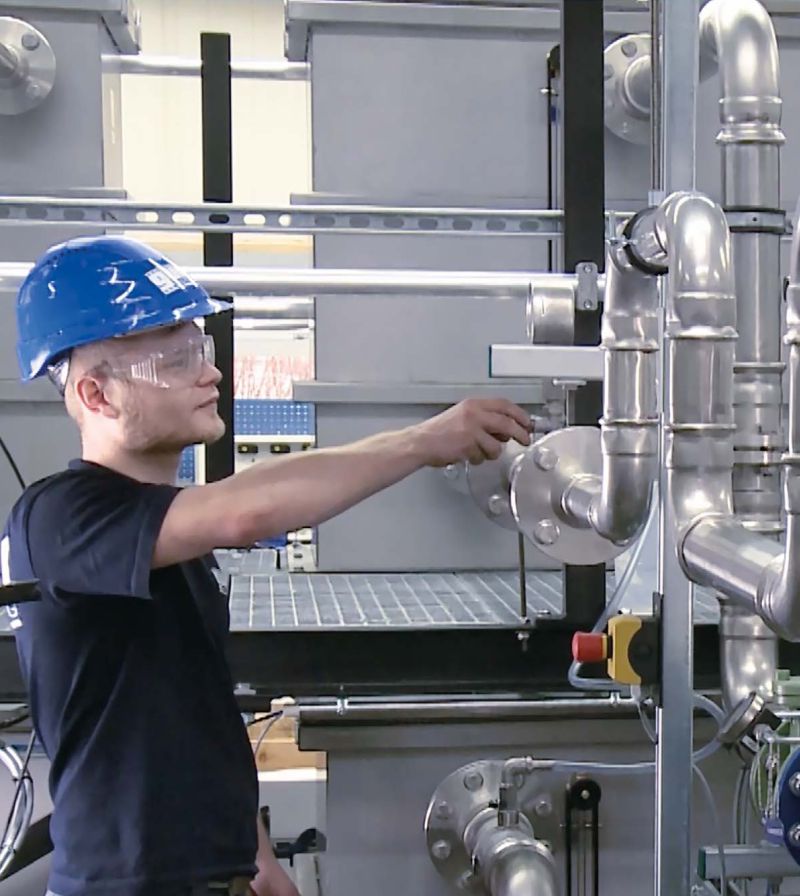

GUNT training systems for industry are absolutely authentic:

- handling real-world industrial equipment components

- detailed familiarisation with plants and processes

- familiarisation with and application of industrial automation technology

- operating plants

- understanding and executing maintenance and servicing procedures

- aspects of plant and occupational safety

Complete course concepts with diverse problems can be constructed and the training plant can be the center of training for several weeks.

Product overview

| Product code | Product title | Purpose of use |

| MMTS | Pilot plants for general skills:

Maintenance and control loops |

|

| MPTR | ||

| IUI | ||

| PPT | Training plants for oil & gas industry:

Choice of pumps, phase separation, wellhead operation |

|

| PST | ||

| WaXTOT | ||

| WaXTMT | ||

| IPP |

Pilot plant for chemical industry |

|

| ET 805 |

Training plant for power plant industry |

We work and plan together with our clients.

GUNT offers custom made solutions.

Is your company active in another field?

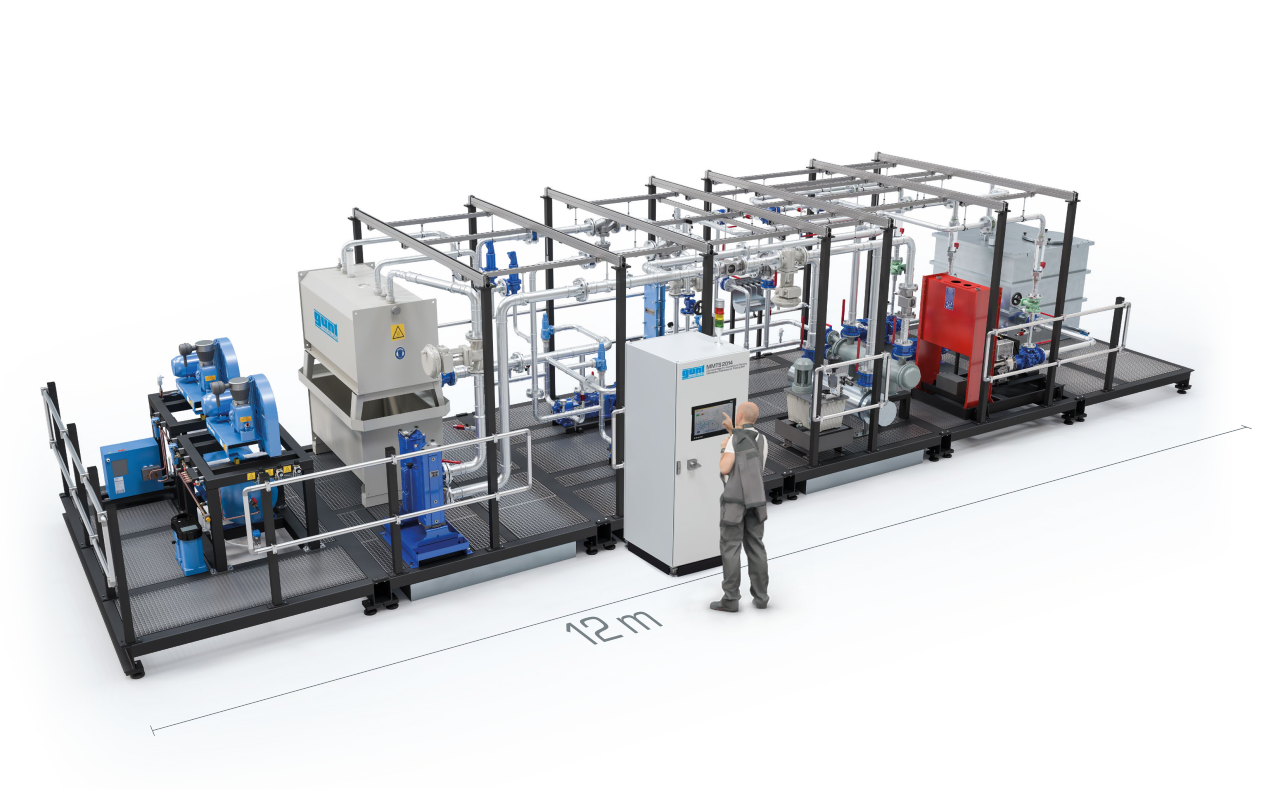

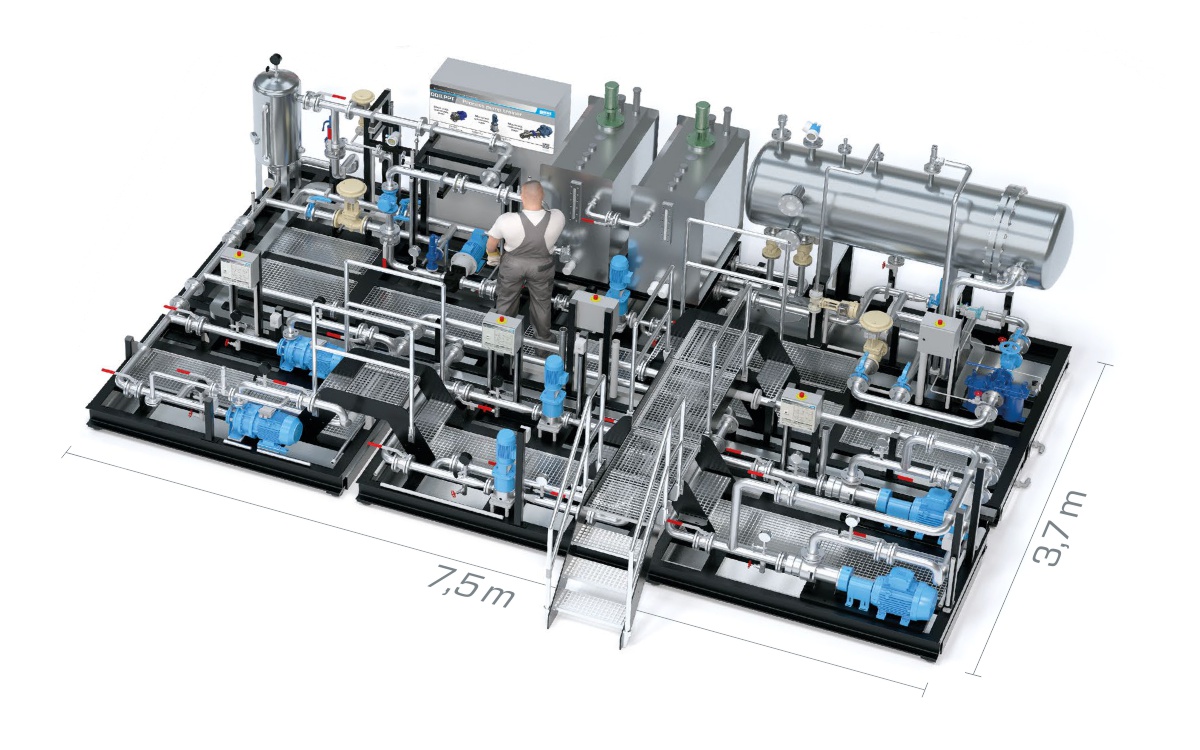

MMTS

Mechanical Maintenance Training Skid

Training plant for maintenance and operation

- oil circuit with heating

- water circuit for closed-circuit cooling with wet cooling tower

- plant operation and maintenance

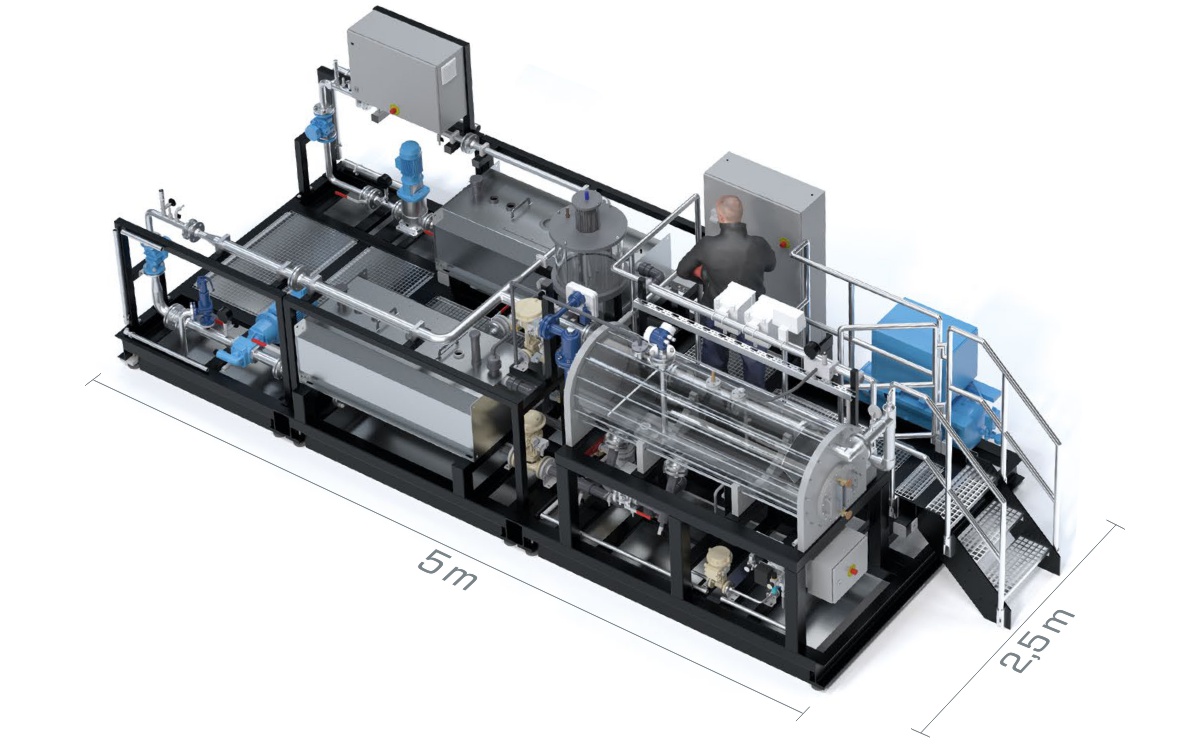

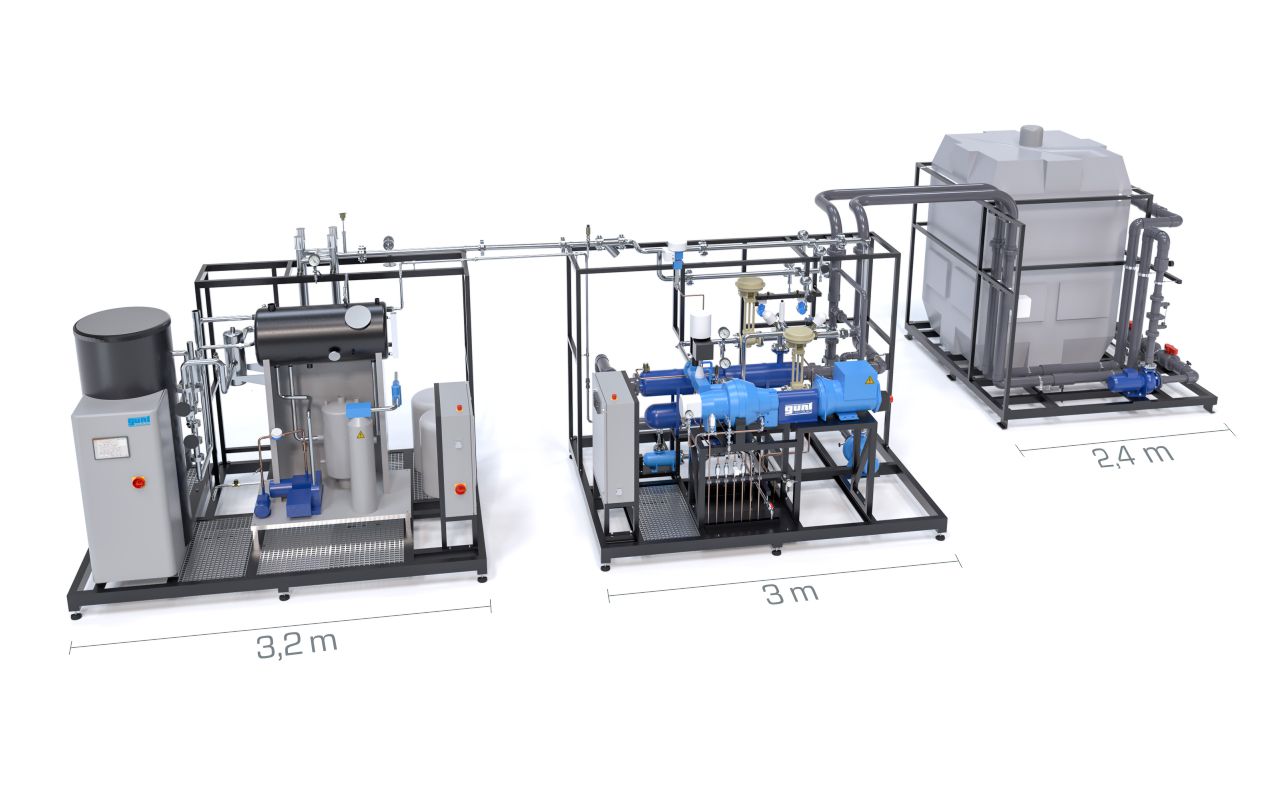

MPTR

Main Process Training Rig

Training plant for pipeline and pump systems

- two separate units for two trainee groups

- plant operation and maintenance

IUI

Industrial Unit for Inspection

Training plant for inspection

- demonstration plant simulates typical processes

- thermal reactor

- steam-driven auxiliary pump system

- compressed air station

- typical electrical cabling with a variety of electrical components

PPT

Process Pump Trainer

Operation and comparison of three different pump types in various operation modes

-

single stage centrifugal pumps, multistage centrifugal pumps, multiphase twin screw pumps

- operation in line or parallel

- simulated crude oil as working medium

- three phase separation after passing the pump section

PST

Phase Separation Trainer

Separation of simulated crude oil into air, water and oil

- transparent phase separator

- three-phase separation using gravity

- two static mixers to blend oil, water and air into new synthetic crude oil

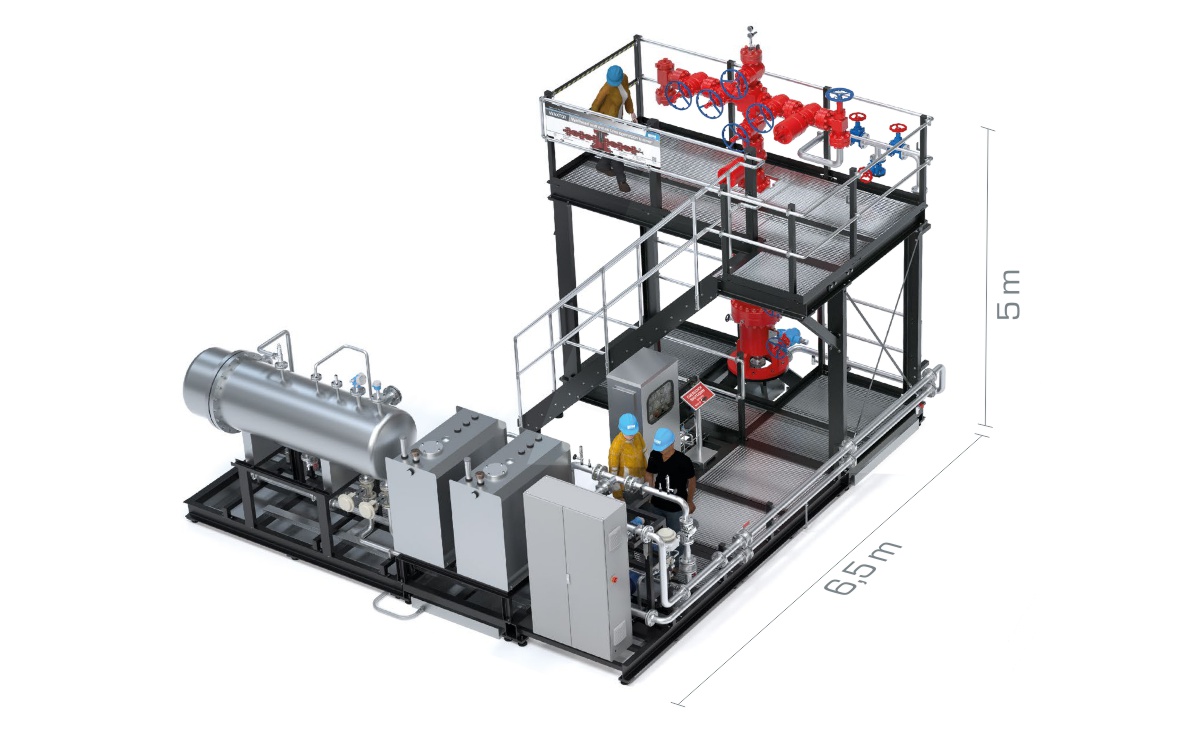

WaXTOT

Wellhead and Xmas-Tree Operation Trainer

Operation of a wellhead with a standard wellhead control panel

- wellhead with several valves and casing spools

- X-mas tree with various master valves, choke valves and wing valves

- supply unit for synthetic crude oil

- operation and control

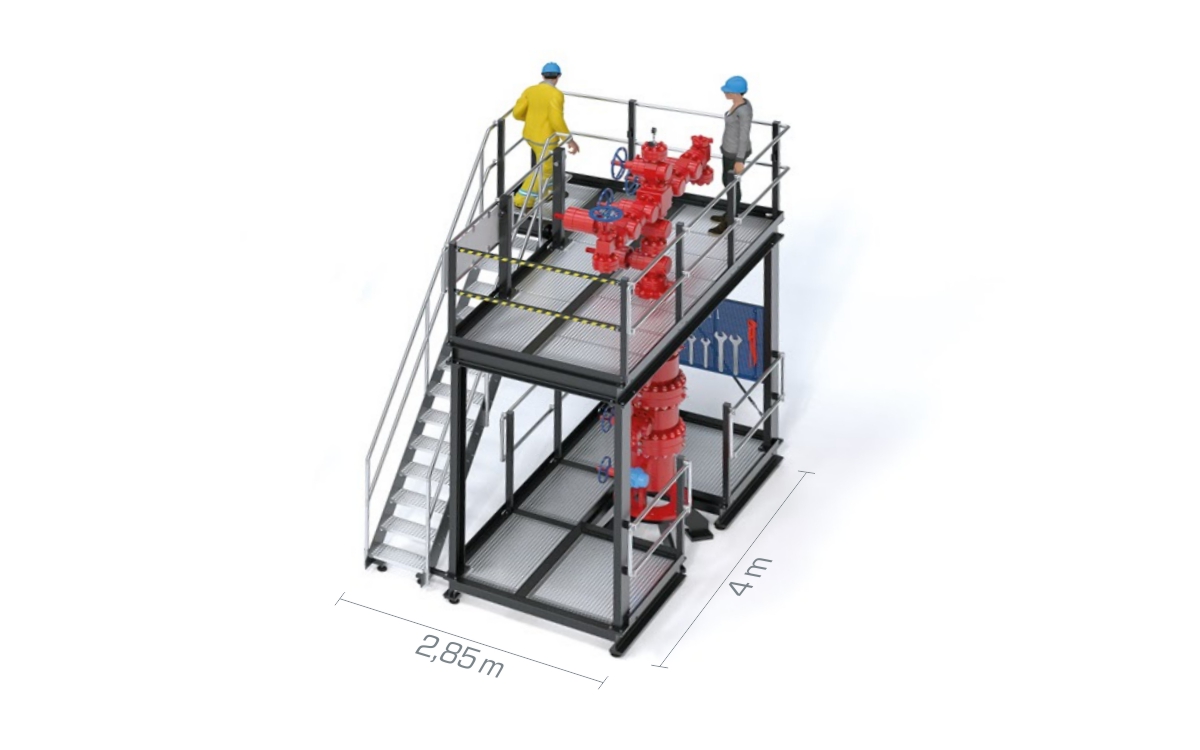

WaXTMT

Wellhead and Xmas-Tree Maintenance Trainer

Maintenance trainer for a standard wellhead

- wellhead with several valves and casing spools

- X-mas tree with various master valves, choke valves and wing valves

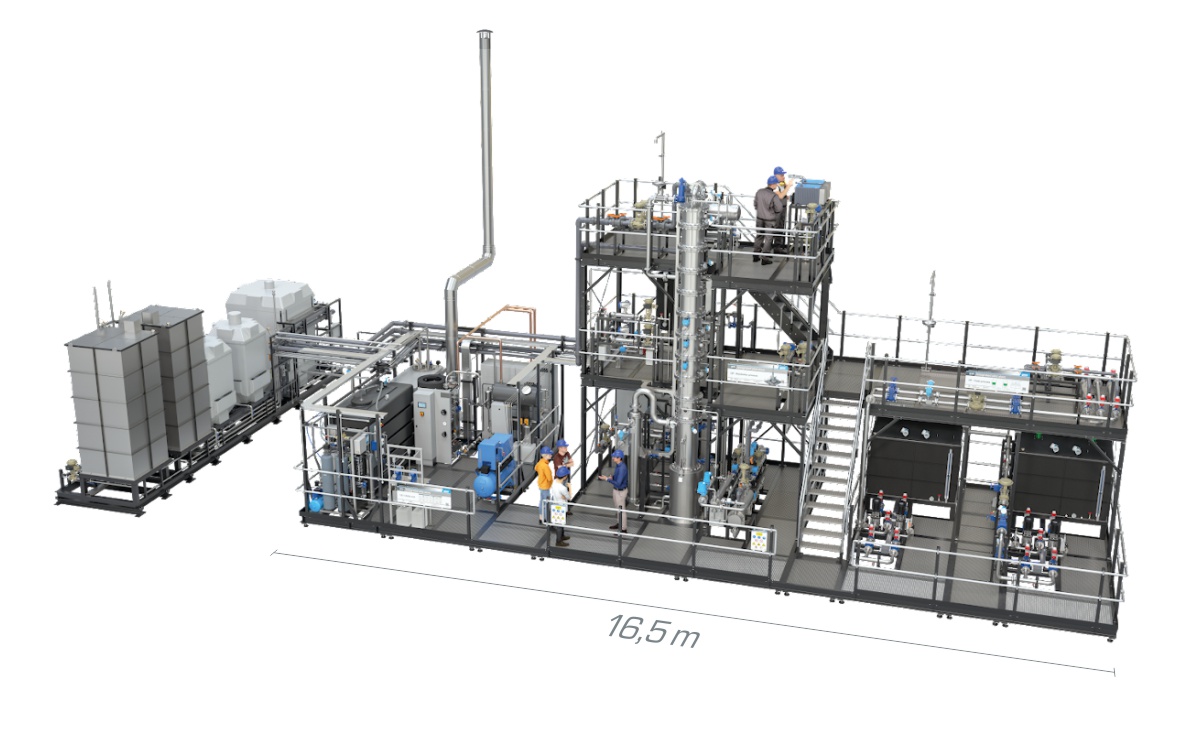

IPP

Integrated Pilot Plant

Training unit for the operation of a process plant

- operation using a water / ethylene glycol mixture

-

combination of a common field process with a distillation process

- field process including tanks, heat exchangers as well as pumps, cooling and control loops

- distillation process with rectification column to separate the water / ethylene glycol mixture

- utility unit for supplying both processes with auxiliary media

- complex process control system

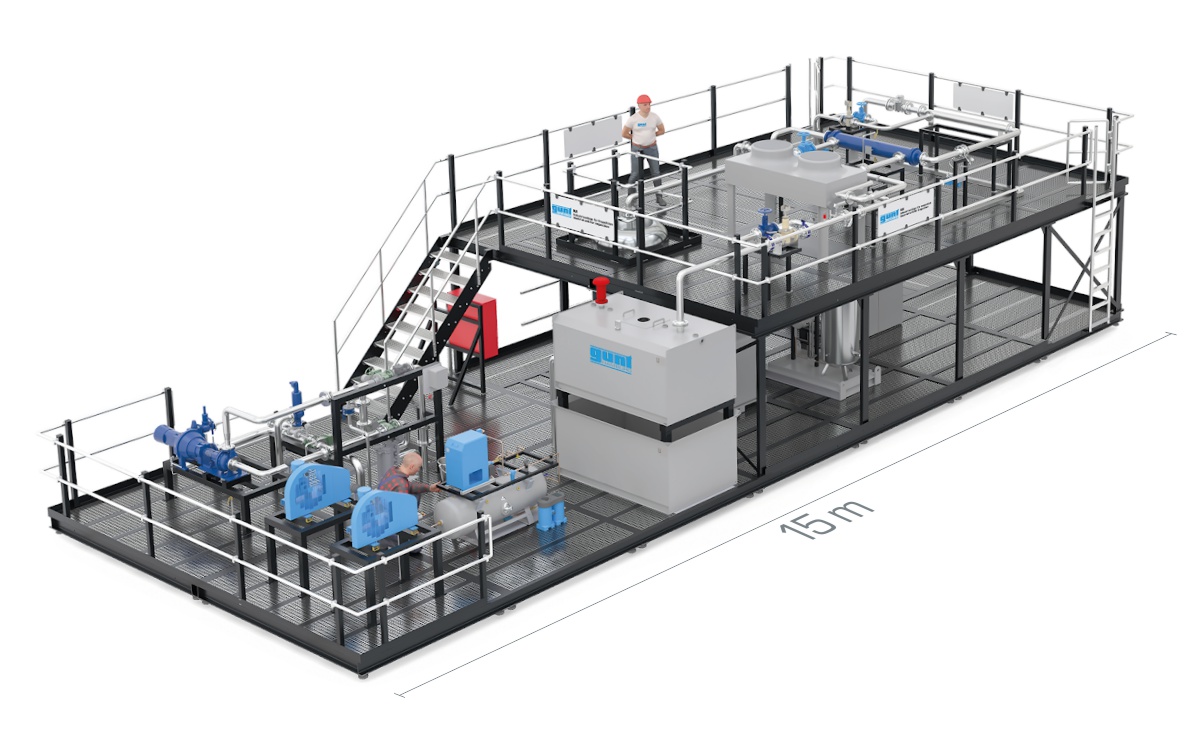

ET 805

Steam power plant

Power plant operation with steam turbine, start and shut down

- feed-in to the grid

- wet cooling tower, feedwater treatment

- plant operation and evaluation

- maintenance and safety aspects

Plant control and data acquisition

Training and pilot plant from GUNT are equipped with different systems for plant control and data acquisition. An overview of the installed system for each plant can be found below.

| Training / Pilot plant | Plant control | HMI |

|

MMTS Mechanical Maintenance Training Skid |

GUNT software based on SCADA |

Touch screen or PC with GUNT software |

|

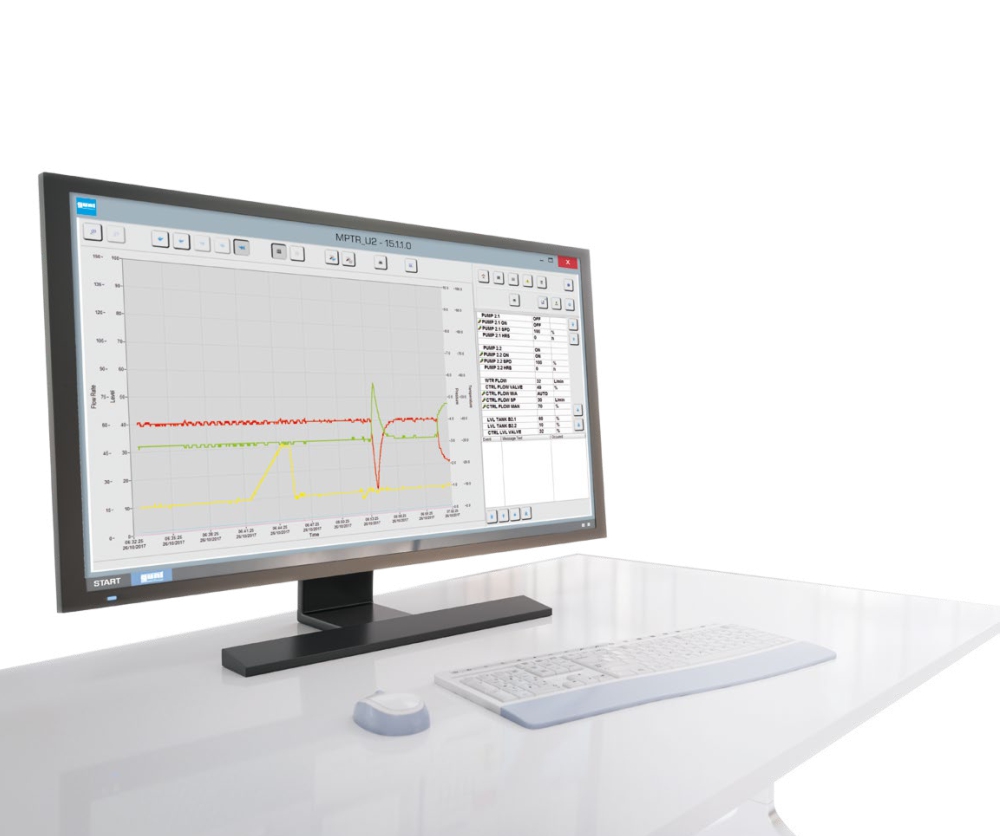

MPTR Main Process Training Rig |

PLCs and industrial PID controllers connected to a SCADA system |

Touch screen or PC with GUNT software |

|

IUI Industrial Unit for Inspection |

- |

- |

|

PPT Process Pump Trainer |

Distributed process control system |

PC with process control system |

|

PST Phase Separation Trainer |

Distributed process control system |

PC with process control system |

|

WaXTOT Wellhead and Xmas-Tree Operation Trainer |

Distributed process control system |

PC with process control system |

|

WaXTMT Wellhead and Xmas-Tree Maintenance Trainer |

- |

- |

|

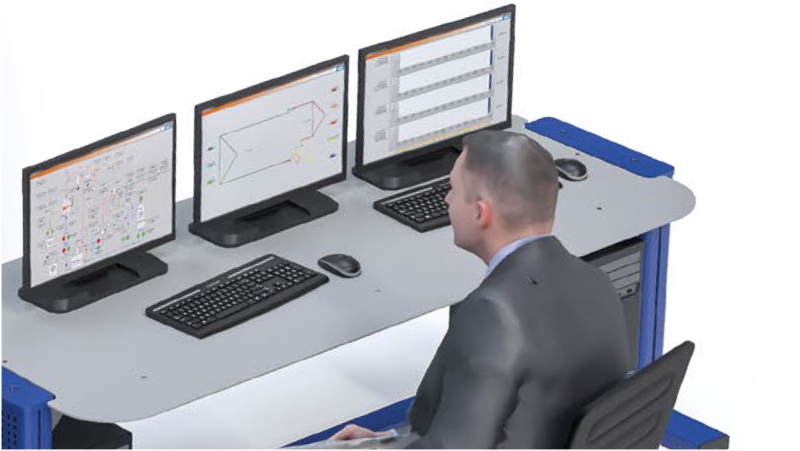

IPP Integrated Pilot Plant |

Distributed process control system |

Central terminal station (ProPlus) with quad-display setting |

|

ET 805 Steam power plant |

Process control system based on Ethernet and PLC |

PC with GUNT software |

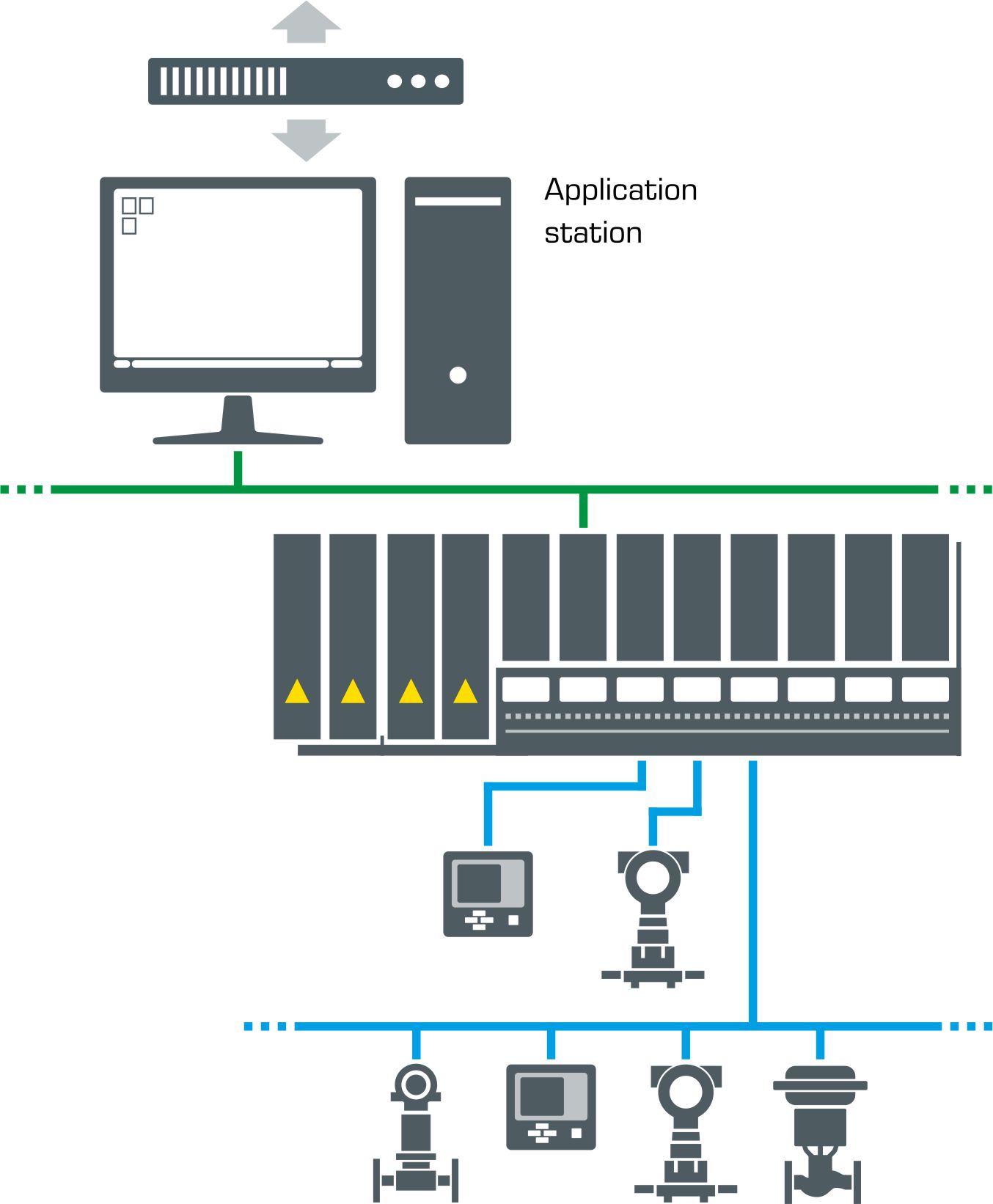

Process control system

The distributed control system is often used in the process industry. It provides a wide range of applications and plant management options. The system includes hardware and software for control and visualisation.

- easy-to-use

- state-of-the-art

- harnesses today's predictive technologies

- modular setup

- based on the use of Ethernet control network and PC-based workstations

Process control with GUNT software

Each GUNT software is specifically adapted to the individual plant. It is based on LabVIEW, a graphical programming environment commonly used for data acquisition, instrument control, and industrial automation.

- intuitive user interface

- display of measured and calculated values in related system context

- versatile graphical representation of measured values

- recording of measured and calculated values even during long periods of time

Plant control via touch screen

The MPTR training plant is operated using a touch screen with integrated PLC. The user interface covers the following features:

- intuitive user interface

- clear process diagram for

- display of measured values

- switch components on and off

- separate views for controller settings

- view messages

Download