ET 805

ET 805

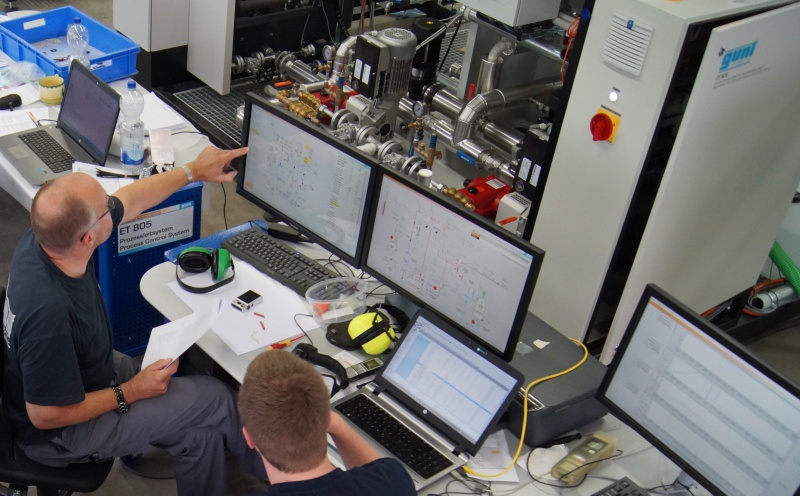

Steam power plant 20kW with process control system

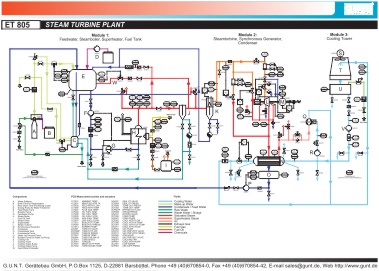

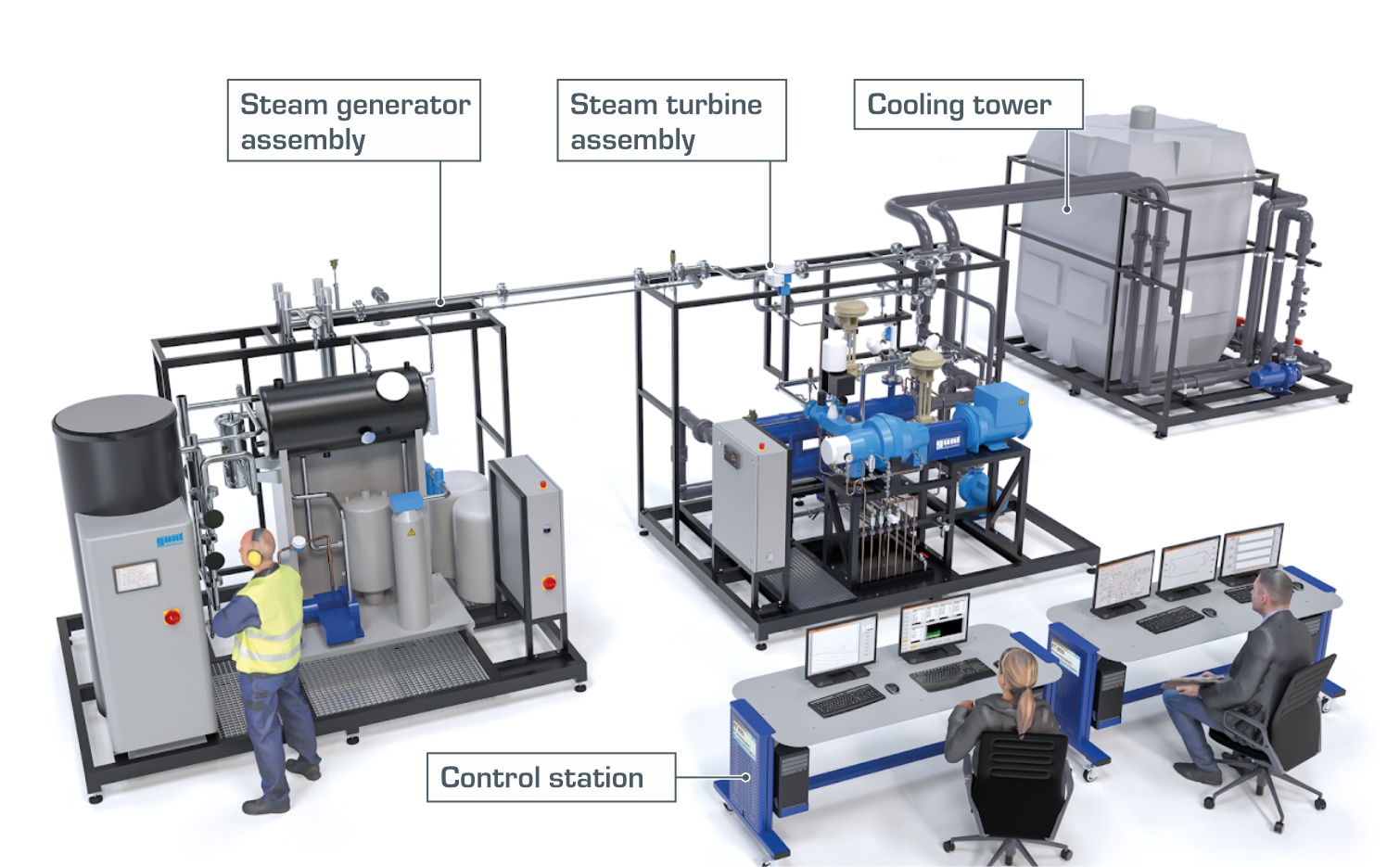

The ET 805 steam turbine is a laboratory scale steam turbine plant consisting of three separate modules and a control station.

This unit allows all relevant properties of a steam turbine power plant to be investigated and to be demonstrated by measurements. The integrated process control system (PCS) enables students to practice operation of an automated power plant.

All of the important variables for the process are clearly represented in process diagrams and are converted into characteristic values.

Modules of ET 805

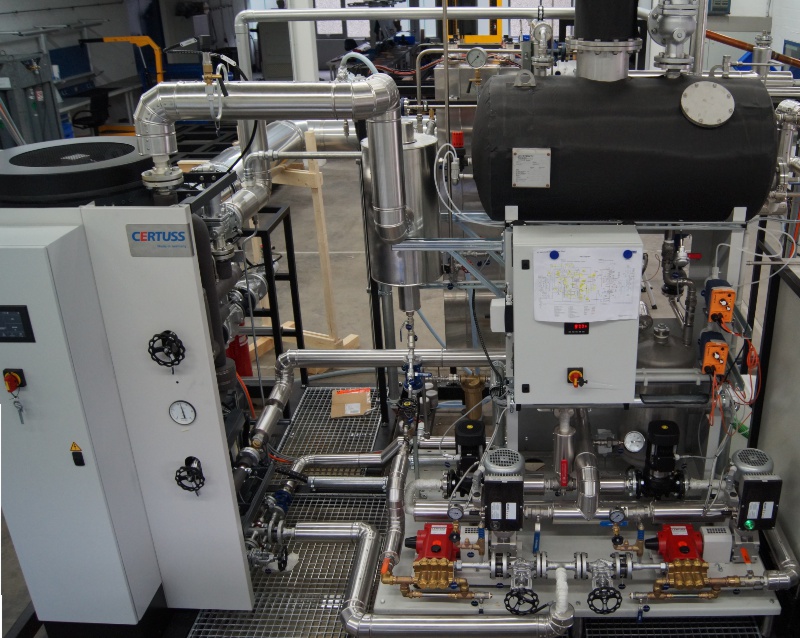

Steam generator assembly

A gas/oil-fired once-through steam boiler and a downstream electric superheater generate superheated steam. The feedwater circuit is equipped with a water treatment system with ion exchangers and chemical dosing.

- continuously operating water conditioning unit for the production of soft water

- degassing unit with feed water tank and continuous water conditioning with 2 metering pumps

- gas- or oil-fired steam generator with booster pumps and feed water pumps

- electrically operated superheater

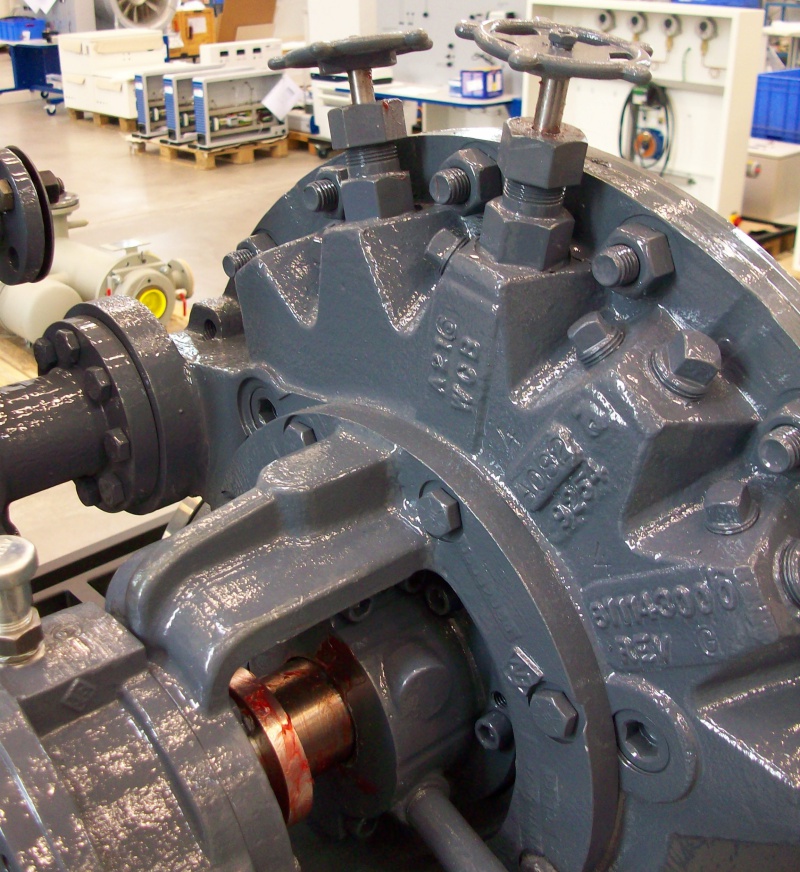

Steam turbine assembly

The superheated steam is fed to a single-stage industrial turbine with speed control. This drives a synchronous generator which can be operated in grid connected or stand-alone mode. The exhaust steam from the turbine is condensed and fed back to the feedwater circuit.

- single-stage steam turbine

- water-cooled condenser with condensate pumps and water jet air pump

Wet cooling tower

A wet cooling tower for a closed water circuit for recooling the cooling water, with cooling water pumps

Control Station

The steam power plant is equipped with a PLC based control system. The PLC connects the electronic measures with the human-machine interface (HMI). The HMI is split to two PCs. The first PC operates the steam power plant and the second PC is recording all measures. An individually suited LabView-based software provides all desired features like easy access to all subsections with their components, measures, trends and controller.

Learning objectives

- design and function of a complete steam power plant with control and regulation system

- start-up, operation, shut down, servicing and maintenance of a steam power plant

- plant control and monitoring via a process control system

- recording and evaluation of the most important operating parameters

- determining: input and output power, component and system efficiency, specific fuel consumption

Download