MMTS

MMTS

Mechanical Maintenance Training Skid

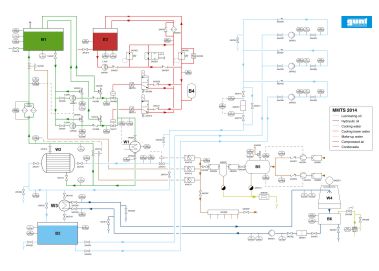

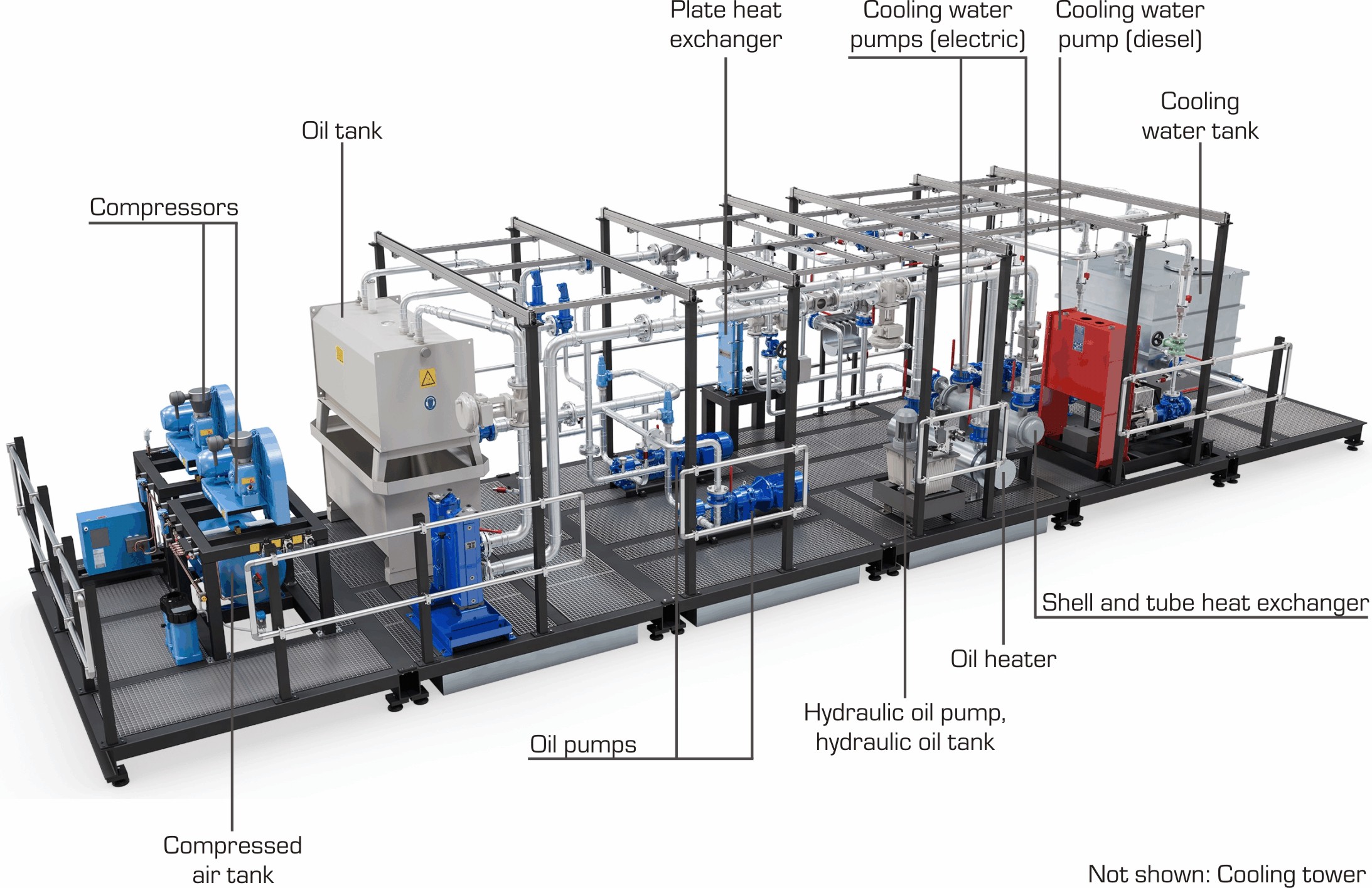

The training system MMTS is used for the maintenance of mechanical components as well as for the measurement and control of various parameters in a piping system with two different working media (oil and water). In real applications, such systems can be found in power stations or in facilities for oil refining and natural gas processing.

The training system MMTS serves to demonstrate the removal of excessive heat from a pump system. In contrast to industrial applications, the training system does not contain any actual engines or turbines. To simulate the heat input of these machines, a heater is used to heat the oil. In the core process of the training system, the heat is dissipated via heat exchangers and a cooling water tower. The mechanical components of the system are subject to maintenance. Various parameters throughout the training system are measured and controlled.

The main circuits and components

- lubricating oil circuit with lubricating oil tank, 2 pumps, heater and lubricating oil cooler; the heater heats the lubricating oil, thus simulating the heat input by an engine or a turbine unit

- cooling water circuit with cooling water tank and 3 pumps for cooling the lubricating oil via the lubricating oil cooler

- hydraulic oil circuit with hydraulic oil tank, pressure accumulator and a pump to supply hydraulically operated valves

- compressed air supply with 2 compressors and pressure tank to supply the pneumatic drives of the open loop valves with compressed air

- cooling tower circuit with cooling tower and cooling tower basin for re-cooling the cooling water circuit via the secondary water cooler

References

Kingdom of Saudi ArabiaJubail Technical Institute (JTI) |

|

Address: Jubail Industrial City

Department: Chemical Engineering

Contact Person: Abdulmohsian Ali Al-Twaijri, Head of Department

Date of Installation: June 2016

Jubail Technical Institute (JTI) is one of the leading institutes in the field of technical training. The academic curriculum is designed to meet the industrial objectives keeping in mind the balance between knowledge and skills. Therefore, 80% of the curriculum is dedicated to the practical side while the theoretical side represents 20%. The GUNT training unit MMTS matches the requirements of this academic curriculum and fits perfectly into the educational concept of JTI. After the successful commissioning in June 2016, the laboratory staff was trained by GUNT engineers. Staff, students and the head of the department are enthusiastic about this training unit.

Download