PST

PST

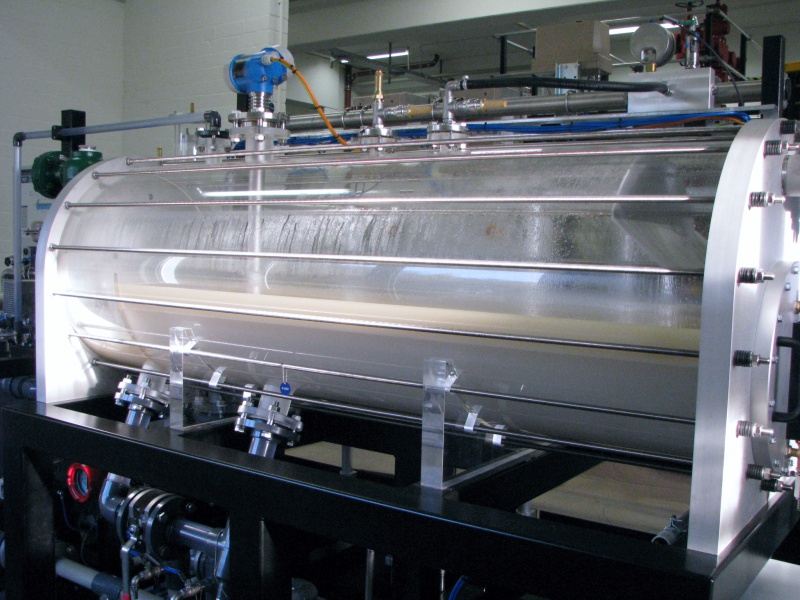

Phase separation trainer

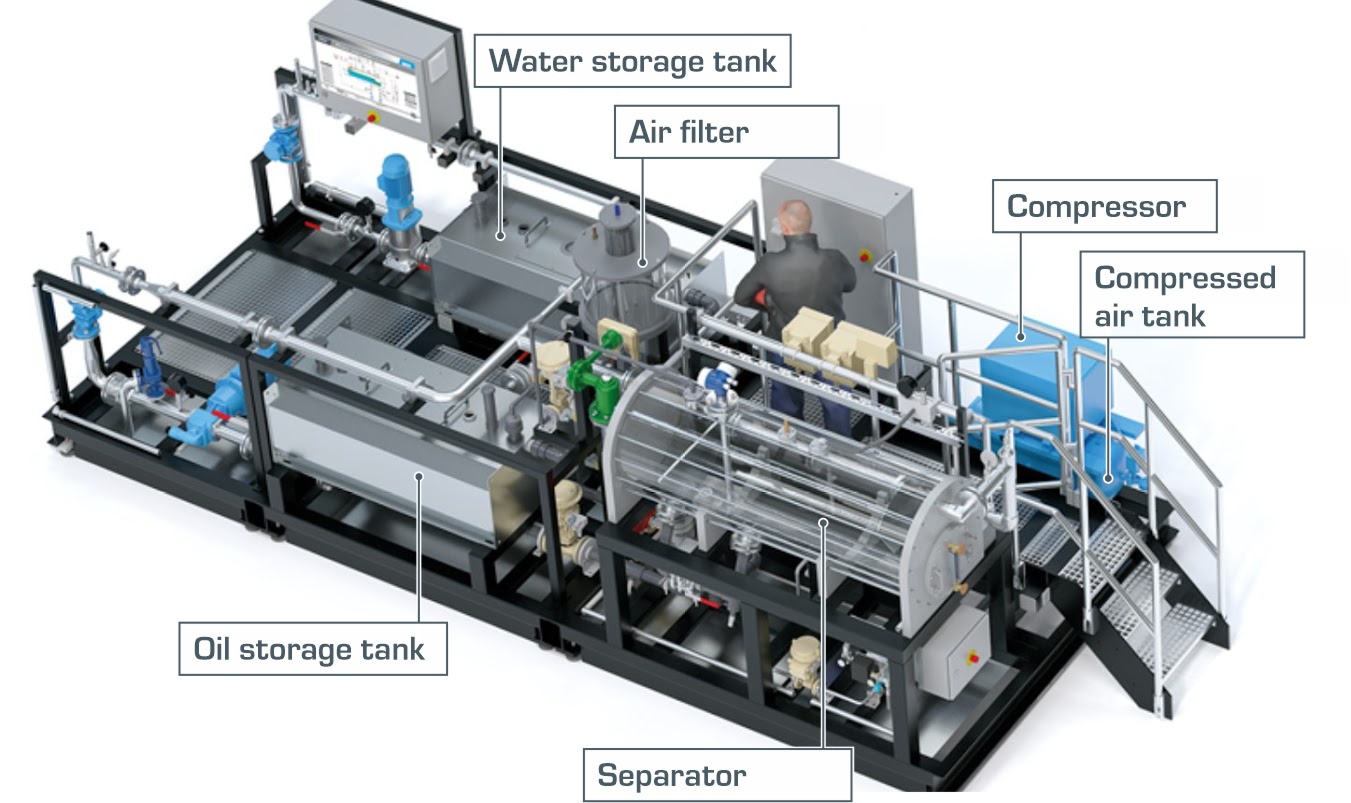

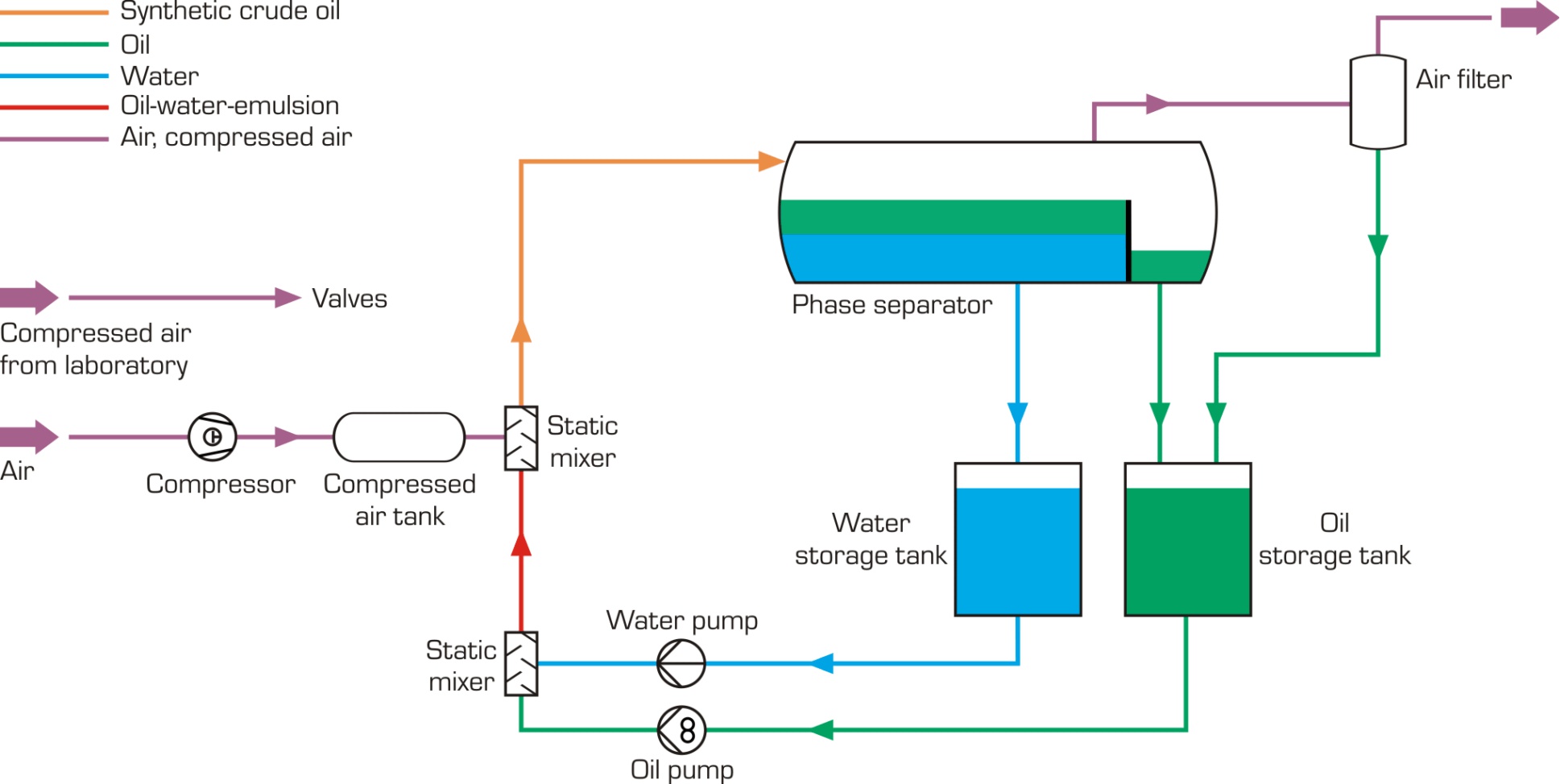

The phase separation trainer demonstrates the separation of simulated crude oil into air, water and oil. Main part of the trainer is a separator using gravity to split up the simulated crude oil. The separator is transparent to enable observing the separation process. After separation, water and oil are stored in tanks whereas the air is vented. Two static mixers produce a new synthetic crude oil for the phase separator to ensure its constant composition.

The separation process

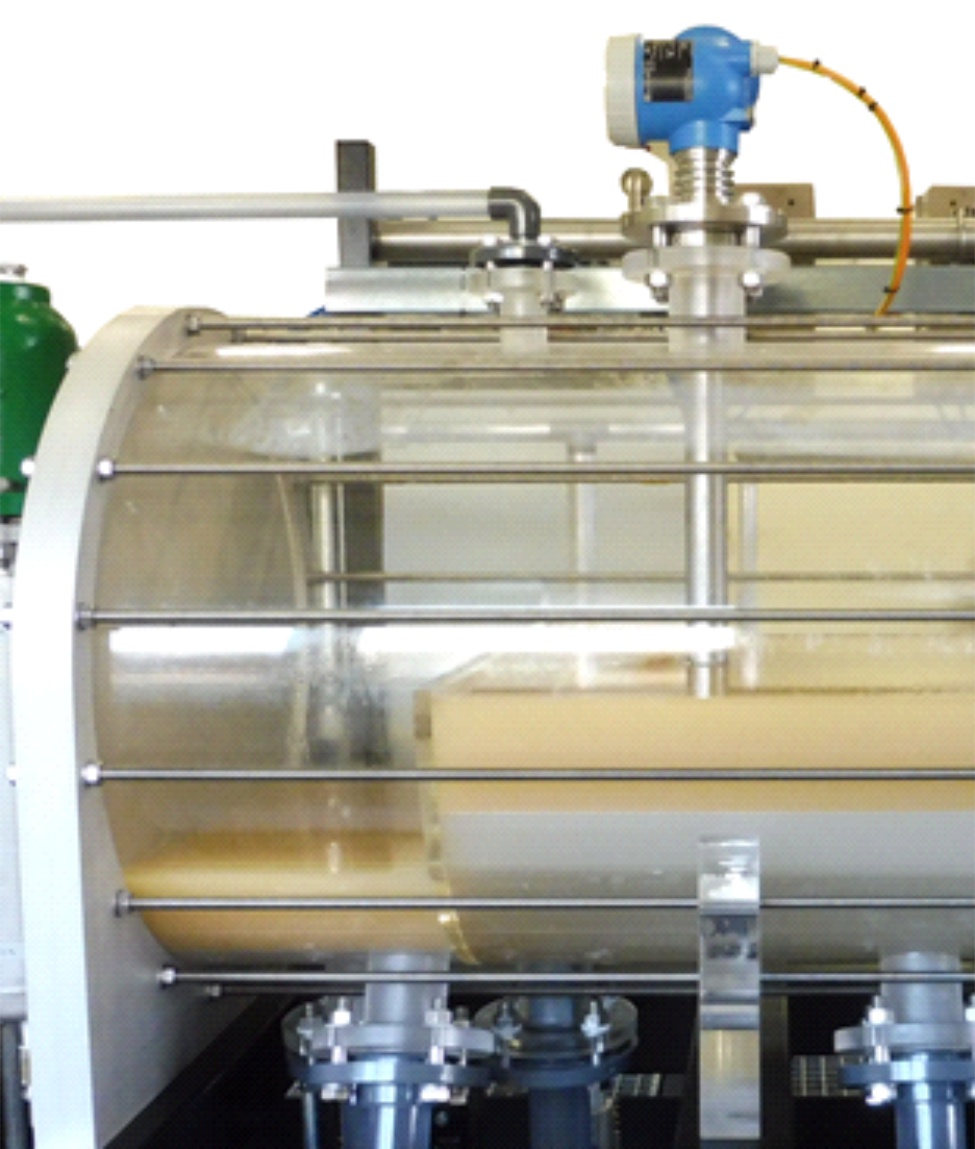

The phase separator is a PVC tank in horizontal position. It is transparent to enable observing the separation process.

The synthetic crude oil enters the phase separator through two vortex nozzles. A first weir made of a perforated plate serves to calm the flow. The separation process itself is driven by gravity. In front of the second weir, water accumulates as denser phase at the ground of the phase separator and oil as lighter phase at the top. Air collects above the oil and is vented to an air filter. There, oil is separated and returned to the oil storage tank. From the phase separator, water and oil are recycled to the storage tanks. Pumps forward both media to static mixers. Compressed air is added and blends the mixture to synthetic crude oil.

Downstream of the phase separator, samples of water and oil can be taken. A water cut meter also measures the contents of water in the oil.

Learning objectives

General learning objectives

- process engineering

- instrumentation & process control engineering

More specific learning objectives

- reading piping and instrumentation diagrams (P&IDs), locating appropriate components

- behaviour of control loops (temperature, pressure and flow)

- setting parameters at PID controllers (proportional, integral, derivative)

- three phase separation

Download