A complete work process when repairing work machines such as pumps consists of the following steps: assembly – alignment – test. The trainer described here was designed with industrial conditions in mind and is primarily intended for the practical training of maintenance engineers. It also offers a variety of topics and starting points for training in vocational schools.

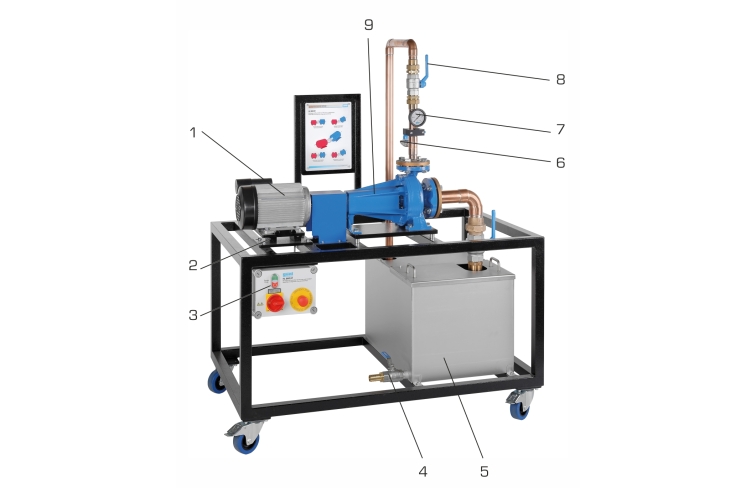

The HL 960.01 trainer enables students to practise the entire maintenance process. On its own, the trainer can be used for assembly exercises with the option of aligning the drive and the pump. Combined with HL 960 Assembly station: pipes and valves and fittings, the HL 960.01 trainer can be used as a test system for the completely assembled piping system.

The trainer consists of an electric drive motor, a standard pump and a piping system with storage tank and can be operated independent of the water supply mains. Students can practise exchanging pumps for inspection or repair as part of the assembly exercise. The exercises cover the entire system and its individual subassemblies. A manometer displays the pressure at the outlet of the pump.

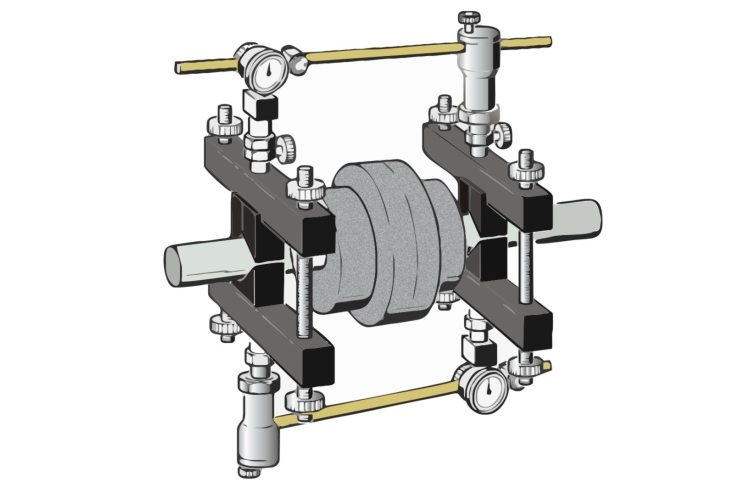

The position of the electric motor can be adjusted in three directions for alignment purposes. The alignment can either be checked in a conventional manner with a straight edge or with the reverse alignment method using two dial gauges. Non-contact, microprocessor-aided methods can also optionally be used (specific alignment systems are not included in the scope of delivery).